I’ve had several retailers ask how I would source content for their 3D printing service. My standard answer is from at least three sources – designers, manufacturers, and consumers themselves.

Certainly individual designers would contribute (that’s where 3DLT gets its 3D printable files now.) We’ll see a huge spike in that effort when we go retail. After all, what designer wouldn’t want a fast track to sell their products through a huge chain store network? To drive the right types of content, we’ll run various promotions with them.

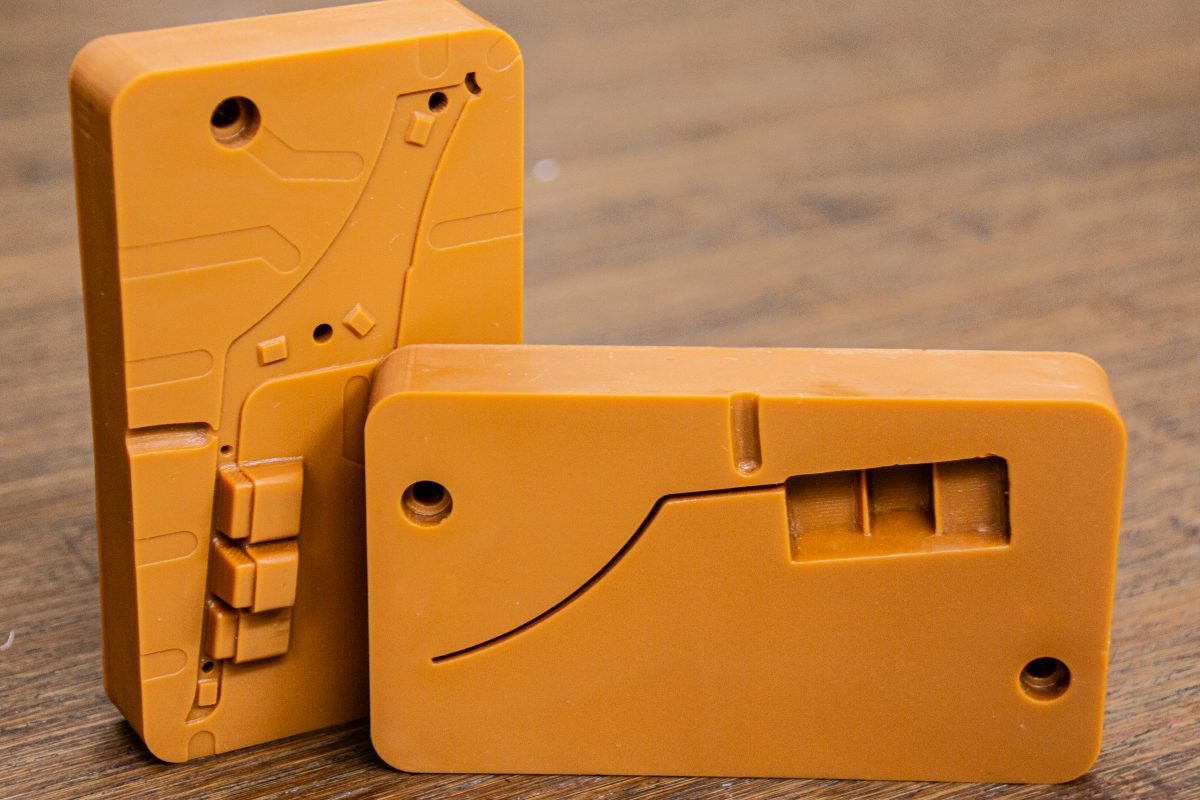

Currently, we conduct monthly “theme drives” with our designers to fill out specific categories. Over the last year, we’ve done theme drives around jewelry, toys, holiday items, and tech accessories to name a few. We’d also conduct less frequent, but more aspirational “innovation challenges,” with the goal of crowdsourcing new products and potentially, entirely new product categories. It’s also an opportunity for us and our partners to tackle big problems that could potentially have a worldwide impact. Imagine if our gun safety initiative, conducted earlier this year, were sponsored by Bass Pro Shops, or another outdoor retailer. The exposure, impact, and results would be amplified immensely.

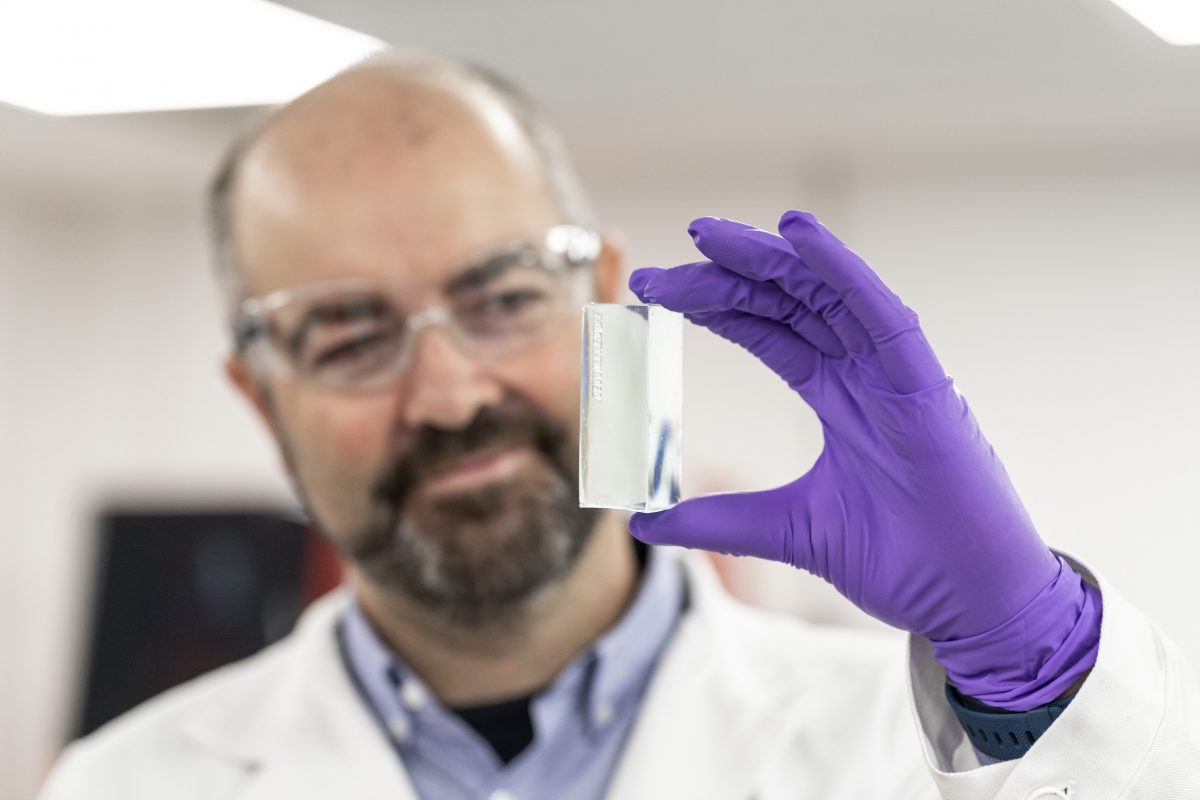

I’ve also addressed the potential impact of 3D scanning. The vast majority of physical products in our world don’t have a digital equivalent. They were designed as blueprints, before the invention of computer aided design (CAD) software. Many of those products are no longer under any kind of intellectual property protection. Even now, people are combing the patent office’s database, looking for products that were invented, and may have even been produced and sold successfully, only to fall out of favor years later.

Just because there is no longer enough demand to support mass manufacturing, doesn’t mean a product couldn’t or shouldn’t be available. 3D printing makes that possible, but requires a digital file. While an original blueprint can be rebuilt in CAD by an industrial designer or engineer, many more products and parts exist without technical drawings. Even in the cases where they do, at some point you have to ask if it makes more sense to solve the problem with labor or technology. While it might take a designer hours to recreate a product, 3D scanning could allow them (or us) to do it in a fraction of the time.

It seems likely that 3D scanning could soon be as ubiquitous as our ability to snap photos. The recently introduced Structure Sensor for instance, attaches to an iPad and allows anyone to scan three dimensional objects. Microsoft has taken it a step further. Their 3D Object Reconstruction and Recognition research team recently presented a workflow that will allow anyone to scan a 3D object with any smartphone or tablet. Using the device’s camera, an image is captured and pushed to the cloud where the computational power exists to render it in 3D. Last year that would have seemed like science fiction and five years ago, we’d all be asking what the heck clouds have to do with phones.

Further, content could come from the manufacturers and consumer packaged goods (CPG) companies who supply retailers now. For them, digital manufacturing could offer an entirely new revenue stream. Of course, not all current products would be candidates – but some would.

Some of the big categories for mass market retailers include:

- Electronics

- Personal care

- Apparel

- Storage / organization

- Kitchen appliances

- Toys / baby

- Furniture

- Outdoor living

- Sports / fitness

- Pets

- Jewelry

3D printed products can play in nearly every one. From smartphone cases, to hair clips, belt buckles, salt shakers, pizza cutters, games, cabinet knobs, garden tools, and automotive accessories, opportunities abound.

Just yesterday in fact, I was at Hauer Music (no relation) in Dayton, OH shopping with my family. From guitar picks to custom knobs and instruments themselves, it seemed that everywhere I looked there were opportunities for 3D printed products. Who better to supply those than the manufacturers who supply mass-produced versions today?

Beyond the product itself, CPG’s have an opportunity to leverage 3D printing in their in-store promotions. In fact, every year, consumer packaged goods companies launch over 50,000 promotions at retail, and its estimated that 40% of those fail to meet their revenue goals. But still they’re offered.

Why? The most recent research from POPAI, the global association for marketing at retail indicates that 76% of all purchasing decisions are made in-store. CPGs understand this and use in-store marketing to attempt to influence purchasing behavior. They provide point-of-purchase (POP) signage and attempt to optimize the visual appeal of their displays. However, its been estimated that 50% of the POP displays and other marketing collateral supplied by CPGs never make it to their intended location. So, they focus on what’s controllable – their packaging.

While the aesthetics and content of a product’s packaging alone can have a big impact on sales, many brands attempt to magnify the effect with promotions. Sometimes these include instantly redeemable, on-pack coupons, which can allow CPG’s to offer a promotion without making changes to their packaging. On-pack coupons help brands drive impulse sales, encourage larger purchases, and promote other products.

Other times, brands will integrate promotions on the outside or inside of their packaging. This technique is often used in conjunction with a contest or give-away and frequently with a cross-promotion of something else (a new movie for instance.) While consumers still gravitate towards those offering lucrative grand prizes, they’re also interested in contests or sweepstakes that provide instant gratification. Typically they are encouraged to visit a website or use their mobile device, where in exchange for their personal data, they find out what or if they’ve won.

For example, beer brand Stella Artois recently ran a promotion which included a code on the inside of its packaging, allowing consumers to order a custom-engraved beer glass (or chalice, in their parlance.) To receive the reward, I had to visit a website, enter a unique code and some personal data. Once approved, I received a confirmation that my glass was on order and should arrive soon. The only problem was that it took over six weeks for the chalice to arrive. So much for instant gratification!

Brands are beginning to recognize that challenge and are looking for innovative solutions, creating opportunities for 3D printing. For example, liquor giant Diageo recently announced a new product called 3D Scotch. The product has a unique label with raised print that feels three dimensional. It also comes with a pair of 3D (movie) glasses. But what’s really innovative is that it features a QR code on the back of the package which allows the consumer to download a 3D printable file for a bottle sleeve.

As it stands, this is a powerful indication of how CPG’s can leverage 3D printing. But, it assumes the consumer will download the file and print it himself or send it to a service bureau for production. It almost seems as though the target audience for this product ($80 retail) are the affluent buyers of personal 3D printers. It is called 3D scotch, after all. For a niche product which can only be ordered online, this might make sense. But what about mass market products?

Imagine if Procter & Gamble brand, Crest were able to offer a 3D printed toothpaste winder, or even a 3D printed toothbrush as a promotion for its oral care products. Now imagine if those could be printed in-store. Talk about instant gratification! Also, think about how this might differentiate the stores who offer 3D printing from those who don’t. If Kroger for instance, were to partner with P&G to offer the program, consumers would visit just to see it in action. While there, they’d spend on other things.

It would also be an opportunity for Kroger to manage redemptions from retailers who don’t offer 3D printing. Some of those orders would be printed and shipped to the consumer, but Kroger could also offer in-store pickup, allowing them to benefit wherever the purchase was made, and potentially syphoning future business from their competitors.

Now imagine this at scale, with multiple brands participating. For CPGs, it would differentiate their products and lead to all kinds of new opportunities for engagement. Eligibility would still require the consumer to provide their data. It would also better allow the CPG to determine the cost and profitability of their promotion. The cost is deferred until the consumer buys and orders their print. Since the products would no doubt be branded, it would even create a marketing opportunity among consumers standing there watching.

For the retailer, it could offer a wellspring of new content, subsidized by mass-manufactured product sales. Of course, the retailer could also generate content (using the other methods mentioned above) to drive sales of their own private label brands. Big CPG companies spend more than $21 billion annually on advertising, spending approximately 25 cents of every dollar to build brand equity. Store private label brands don’t have these costs and are typically sold on price. Leveraging the store’s 3D printing capabilities might allow them to sell on value instead, while enjoying all of the benefits a CPG would otherwise receive.