ROBO 3D recently conducted a Survey with Northrop Grumman. In it, engineers, analysts, and product support staff were asked if they would prototype more often if 3D printing were more accessible and easier to use. 85% said YES. The respondents were also asked if they saw any additional applications for 3D printing (other than prototyping) within Northrop Grumman. 48% said YES.

Now, we might debate where and how they should get access to 3D printing, but one thing seems clear. Access begets innovation. People who have access to 3D printing think about using it to solve big problems.

Innovation Begets Opportunity

When the Volkswagen “diesel-gate” crisis became public, all the industry analysts were saying the solution would be part software and part hardware – and that “the fix” would most certainly impact fuel mileage and horsepower.

The moment I read that, I thought, “3D printing.” Because I’ve been lucky enough to have access to it, and various other digital manufacturing technologies, I guess I’m wired to think that way, but here’s why it popped into my head just then.

VW would need to create a physical part to help their engines comply. That would require multiple iterations, quick production and a massive supply chain undertaking. Something north of 2 million cars are affected.

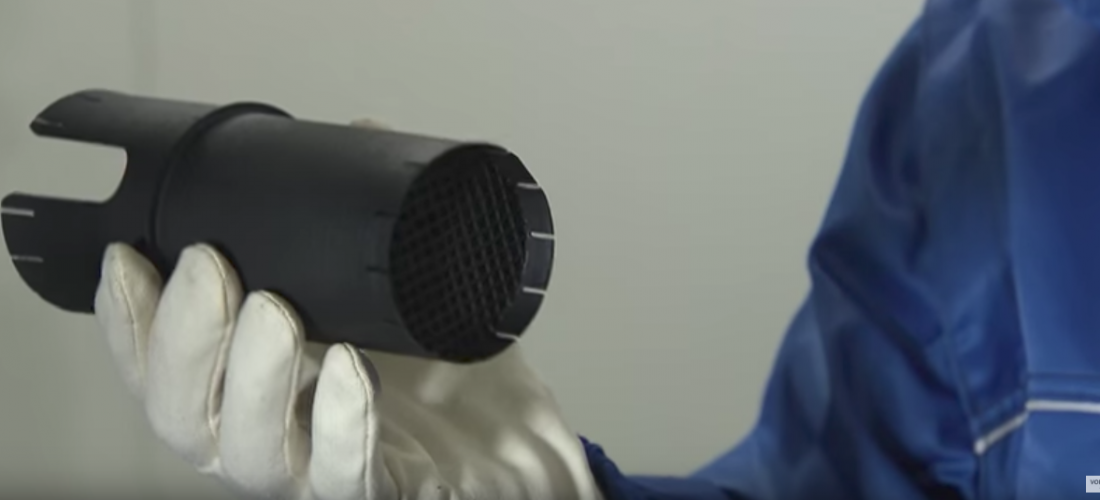

Then today, I saw this:

Go ahead and try to tell me the “flow transformer” in that video wasn’t 3D printed.

Which got me wondering about the “how” and “where.” As in, how will these things be manufactured? And where?

Certainly the plan is to mass manufacture them, ship them to dealerships all over the world, and install them as part of a recall. It’s going to be expensive. It’s a rush job on production, packaging and fulfillment.

What happens if there’s a design change? Scrap it all and start over?

For an order of magnitude more money, Volkswagen could install 3D printers at each of its dealerships and print the parts on site.

Now, first you’re going to say, “3D printing will still cost more.” You’re right.

Then you’ll say, “VW is already in it waste deep, they can’t afford to spend more.” But here’s why they can, and should.

As much as Volkswagen has a massive product liability issue on their hands, they may have a bigger problem with brand perception and consumer trust.

Imagine the PR opportunities. VW announces that it will use 3D printing to help it fix the problem. They’ll be installing 3D printers at all of their dealerships to print the necessary part.

Because “the fix” is likely to evolve over time, new iterations will be made available as updates, printed, and installed as they become available. Maybe even throw in a bonus – customers will receive free fix-related parts for the life of their vehicle?

It’s likely “the fix” will get progressively better. Could it even be customized by vehicle or tuned to specific local standards?

Maybe VW takes it a step further. Because the company is committed to continuous improvement, it decides to open innovation on “the fix.” Interested parties can download the hardware design and submit improvements.

But, what about the upfront cost?

The goodwill alone might cover the upfront investment. But, also think about the other opportunities, from accessories to vehicle customization and beyond. 3D printing could quickly become a profit center for VW and its dealerships.

What about the time and resources needed to build that kind of network?

What about the benefit of crowdsourcing innovation throughout your network of engineers and field technicians?

What about the technology?

It’s available now (the part in the video was 3D printed!) and getting better all the time.

What about implementation?

It will take years to implement “the fix” no matter how it’s handled.

The Bottom Line

Tesla challenged a lot of assumptions recently when, via software download, it enabled semi-autonomous driving.

Volkswagen has an opportunity to turn this crisis into opportunity by providing broader, faster access to innovation.

Will it be expensive? Hell yes!

But for VW, that’s a reality in any scenario.

The benefits of better, faster innovation and a digital supply chain would be a huge advantage for Volkswagen. Their speed-to-market would be unmatched. But beyond that, the transparency inherent in a digital solution would certainly help demonstrate the company’s commitment to open innovation as a means of resolving big problems.

And for VW, its stakeholders, and its customers, that’s priceless.