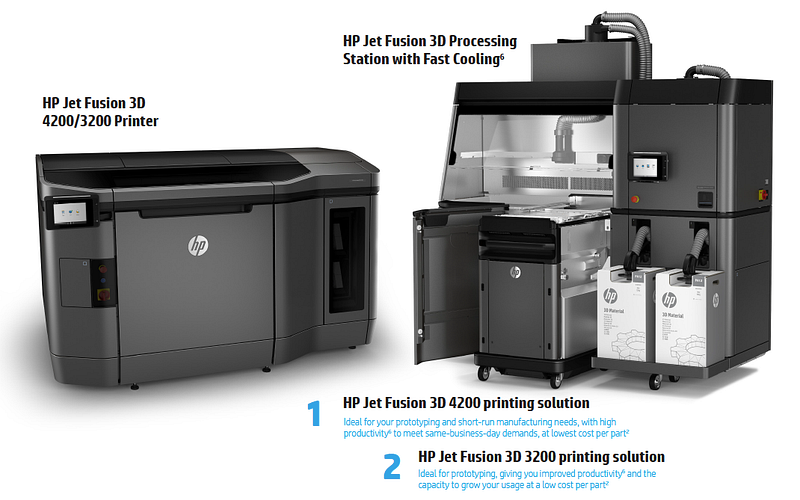

HP officially launched its first foray into 3D printing at RAPID 2016. The company’s offering, which HP bills as the “world’s first production-ready 3D printing system” is powered by it’s unique Multi Jet Fusion printing technology. The announcement actually includes two new printers; the HP Fusion Jet 3D 4200 and HP Fusion Jet 3200, as well as the separate HP Jet Fusion Processing Station.

Multi Jet Fusion

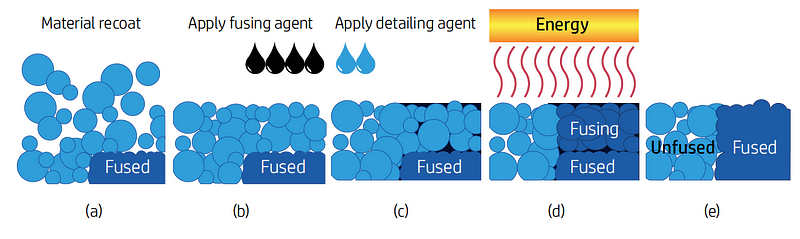

HP’s Multi Jet Fusion technology allows for 3D printing of functional parts at the voxel level. A “voxel” is a three dimensional pixel, and HP’s printing process uses different “agents” that can be applied to any voxel in a given part, enabling unique properties for each. In the first iteration, this allows the machine to solidify the majority of voxels in a part, while adding fine detail to the edges. In later iterations, it could enable the creation of full color parts in addition to giving them many other unique characteristics.

It essentially works like this. A digital file is submitted to the printer where it is prepared for production. It is printed in a bed of material powder. A fusing agent is applied to the majority of the part and a detailing agent is applied to the edges. Then energy (heat) is applied, which causes the agents to react. This hardens and details the part while also separating the unfused material from the part itself. This process is repeated layer-by-layer until the part is completely finished.

The agents are applied using HP Thermal Inkjet arrays. These are similar to the inkjet heads used in the company’s production 2D digital inkjet presses. They provide incredibly fine detail and are capable of delivering many different inks. In 3D instead of laying down ink, they deliver the agents that solidify and detail each part.

“Our 3D printing platform is unique in its ability to address over 340 million voxels per second versus one point at a time giving our prototyping and manufacturing partners radically faster build speeds, functional parts, and breakthrough economics,” Stephen Nigro, president of HP’s 3D printing business, said in the company’s press release.

Future Capabilities of MJF

Out of the gate, HP’s 3D printers will be limited to printing one color (black) in thermoplastics like nylon. But in the future, Multi Jet Fusion technology and other, new materials will enable an entire range of applications.

Color is high on the agenda. With 2D digital printing, the ability to affordably and quickly print in full color created a “hockey stick moment” for the industry. It is widely believed that color could have the same effect in the 3D printing industry. HP’s inkjet arrays deliver color in 2D today and soon will offer similar capabilities in 3D.

In fact, HP is already producing 3D parts in full color in its laboratory:

Not only can the color of each voxel be tuned (pardon the pun), but if you look closely, you’ll notice that the detail of each string in the guitar. That particular sample is about 3 inches long and yet, each can be plucked independently. They’re not much thicker than a human hair!

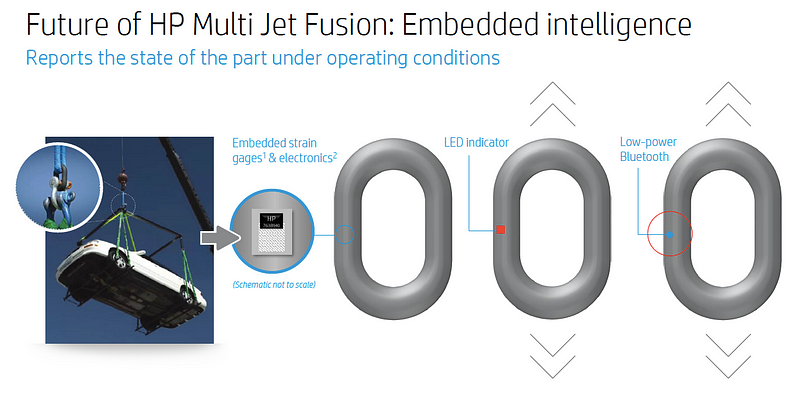

That’s really just the beginning. Multi Jet Fusion could also provide the voxels in parts with other unique characteristics. For example, the surface of parts can vary from smooth to rough to provide viscosity in some areas and friction in others. The technology can also enable parts that are soft and flexible in some areas, yet rigid and hard in others. Depending on the material it could even create parts that are opaque in some places and translucent in others. Going even further, it could enable parts where portions exhibit electrical or thermal conductivity, opening all kinds of doors with embedded information and intelligence.

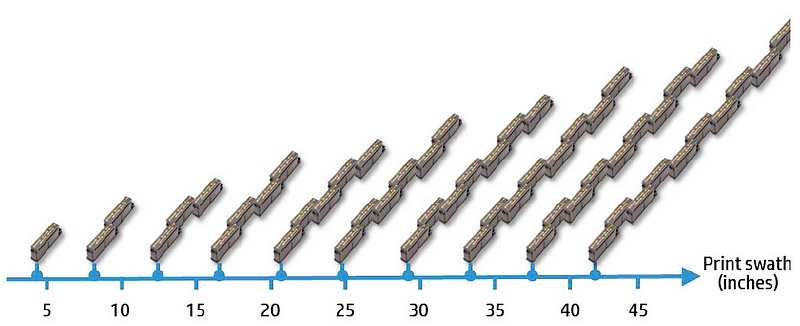

It’s not just the material characteristics that conjure possibilities, but also the inkjet technology itself. In 2D printing HP has been able to build very large machines that produce in very wide formats. The company is considering the same approach in 3D printing. The build area for the first iteration of 3D printers is 16 x 12 x 16.” This is achieved by stacking an array of 3 print heads across the build path. But, HP is also working on larger formats where many more inkjet heads are stacked, allowing build areas of over forty inches wide!

Not only would this enable the production of very large parts, but in high-volume environments could enable even more productivity and lower cost of smaller parts.

Workflow

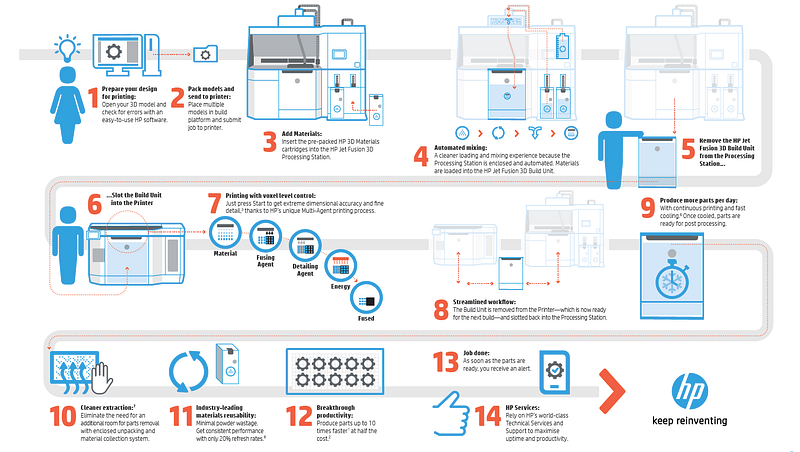

One of the big surprises for me, was finding out that HP’s system actually includes a group of machines working in tandem. Frankly, I expected to see one machine doing all the work. But, once you understand the workflow, it makes logical sense.

As expected, it starts with a user sending a digital file to the printer. But, after that, things start to diverge. With today’s current standalone 3D printers, most of the remaining tasks are completed in one box. To dramatically improve productivity, HP technology accomplishes these tasks using three separate devices including the printer itself, a processing station and a build cart.

The processing station is first used to load material into the build cart. By going this route, (and because of the unique characteristics of MJF) HP is actually able to recycle the majority of material from previous builds. This is pretty revolutionary in 3D printing. With selective laser sintering (SLS) for example, most of the material used in a build is simply wasted. Often this can be 70% or more of the material. Since material is often the most expensive component in the production of parts, being able to reclaim it significantly reduces cost.

The processing station mixes recycled material with fresh powder to completely fill the build area. Then the build cart can be removed, and inserted into the printer. The build cart is enclosed, so this process (which in 3D printing is typically messy and requires special clothing and breathing apparatus) is clean and can managed by employees without taking special precautions.

The printer then does it’s thing. It should be noted that a large part of HP’s speed advantage comes from the way materials and agents are fused. In SLS for example, a laser is applied to each point in a part where it quickly heats the powder and creates a voxel. With HP’s technology the combination of Infrared light and heat fuse a large swath of voxels as the lamp moves across the build tray. But in either case, all of this heat must be dissipated before the parts can be handled.

Fast Cooling

With SLS printers, the parts remain in the printer until they are cool, effectively turning the printer into a large oven for several hours or even days depending on the material and density of the parts. With HP’s technology the build cart can be removed once the build is complete. While the cart could be left to sit until the parts are cool, the processing station provides a better option. HP has developed unique “fast cooling” technology to reduce cooling times by as much as 75% (from an average of 40 hours down to 10).

To accomplish this, the build cart is re-inserted into the processing station. Once the parts are fully cooled, the operator is notified and can remove them from the cart. The processing station also includes a finishing area, where parts can be cleaned and prepared for final use. It sort of resembles a salad bar with a “sneeze shield.” As the operator cleans the parts with an air hose, any loose material is sucked back into the recycling container, where it can be reused. The clear window provides visibility and reduces the likelihood of material escaping the station.

Together the three machines enable productivity at each step of production without having to sit idle during other parts of the process. While this is impressive in a stand alone configuration, it gets even more productive in an environment where multiples are used. For example, with one processing station, one printer, and three build carts, one can be loading while another is printing and another is cooling. Once the first is finished loading, the third can be returned to the processing station for faster cooling.

“The new HP Jet Fusion 3D Printing Solution delivers a combination of speed, quality and cost never seen in the industry,” added Mr. Nigro. “Businesses and manufacturers can completely rethink how they design and deliver solutions to their customers.”

Software

In addition to well-trained people and clearly defined processes, orchestrating this kind of workflow requires powerful software. It all starts with the file format itself. In the early days of digital, the 2D printing industry utilized formats like Adobe’s Postscript and HP’s PCL format. The problem was neither allowed for fonts and graphics to be embedded and they weren’t visible on a monitor. The invention and adoption of Adobe’s PDF format changed that, allowing users to create print-ready files that greatly simplified workflow for print shops and service bureaus.

3D printing is undergoing a similar transition. For years, CAD designs have been packaged as .STL files for 3D printing. While they do a decent job of defining the location of voxels in a part, they don’t offer much information about the characteristics of each voxel. HP is working with a consortium of other companies, including Autodesk, Dassault Systemes, Microsoft and others to develop a new file format called 3MF. In addition to mapping the placement of voxels, this format will include detail about color and other characteristics of individual voxels. The development and adoption of a format like this is critical to unlocking some of the capabilities that could be offered by technologies like Multi Jet Fusion.

HP has designed its printer management software to work in conjunction with 3MF. It also works with STL, and is designed to support other future formats, should they be developed. HP has also developed a complete set of API’s and has worked with companies like Siemens to integrate with their existing product lifecycle management workflows.

Once a file is received in HP’s printer management software, errors in the geometry and other fixes are automatically applied. Once that is complete, the file is optimized for production in the build area. In some cases when a user wants to benefit from a fully filled build area, multiple different parts are combined. In other cases, a single part can be “ganged,” where multiple copies are made in one build. Assuming there is room in a build, the system can even allow users to add parts on the fly, once the original configuration has already been mapped.

Materials

HP’s 3D printing solution will launch with two different materials (PA-12 and PA-11), both of which are polyamides designed for high reusability. In layman’s terms, they’re different types of nylon. Other materials are on the roadmap include other polyamides, elastomers, and thermoplastic materials, among others.

To accelerate the development of materials, HP is taking a more open approach. In addition to sourcing materials internally, HP is also exposing its platform to other suppliers. Several big names, including BASF, Lehmann & Voss & Co., Evonik, and Arkema have already jumped on board.

Others are in negotiations and development. Third party materials must be validated by HP and have to be packaged in containers that are compatible with HP’s printers. They will be sold through a materials “app store” hosted by HP. While this strategy isn’t completely “open,” it does allow multiple suppliers to participate and potentially compete against one another on similar substrates.

Part of the intention is to spur innovation. The R&D investment to develop new materials for a new printing technology is significant. If HP were going it alone, they’d have to pick and choose. With multiple companies participating, each can find a niche. In volume applications, there would theoretically be opportunity for multiple brands.

From a customer perspective, it should help drive down cost. From their original announcement back in October, 2014, HP made it clear they are focusing on the production environment. Service bureaus with multiple machines running multiple shifts. While there are many facets involved with calculating total cost of ownership (TCO), in large volumes, materials are typically one of the biggest.

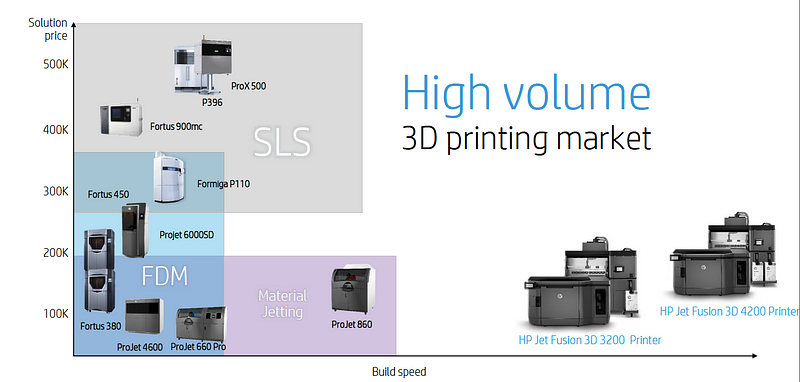

Machine Pricing

While we’re on the subject, I should mention the cost of the equipment. Pricing for the HP Fusion Jet 3D 3200 printer starts at $130,000. The full end-to-end solution, including the 3200 and processing station starts at $155,000. Even with a couple of extra build carts one could imagine being in business for right around $200K.

Frankly I was shocked at such a low price. With all the effort that has gone into research and development of the software, computer hardware, printer and post-processing I expected a higher price tag. Clearly HP intends to spread that cost by selling lots of machines.

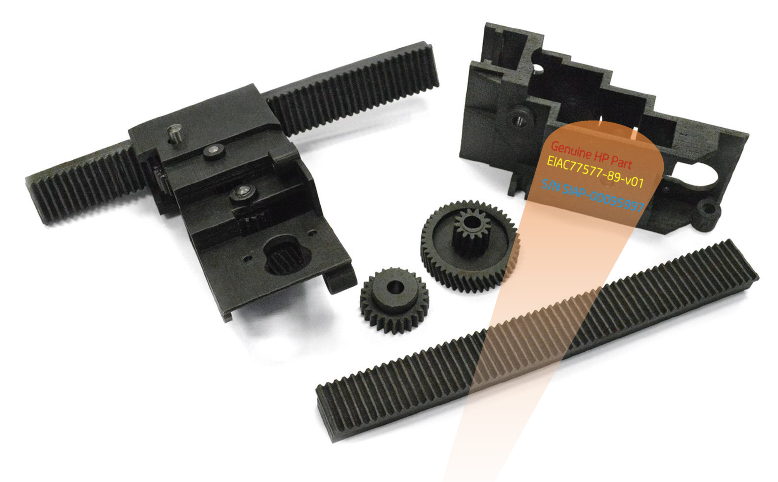

They’ve also decided to “eat their own dog food” in the construction of their devices. HP’s 3D printing system’s hardware includes over 160 plastic parts and over half are themselves 3D printed. This not only allows HP to scale manufacturing by printing those parts “just-in-time,” but could also create a lot of efficiencies in their spare parts supply chain. It’s possible that one HP customer could print parts for another, and theoretically at least, a customer with multiple machines could print their own.

From a competitive standpoint, it puts HP in a position to win against much more expensive alternatives. They claim the output from their machines is half as expensive and ten times faster than fused deposition modeling (FDM) and SLS machines costing $100 — $500K.

As part of their research and development process, HP worked with early customers like Shapeways, Materialize, Sculpteo and Proto Labs to identify requirements and get feedback. One can safely assume that understanding and validating cost against comparable alternatives was an important part of those conversations.

Back to the Future

As mentioned above, the capabilities of Multi Jet Fusion could go way beyond what’s available in this first iteration. Two of the biggest could include embedded information and intelligence. Color for example, could be used as more than a decorative part feature. Barcodes could be used to track parts through a supply chain. It could also be used to differentiate similar parts, simplifying installation. Color could even be used to indicate part wear. Some of that information could be seen in the visible spectrum, while in other cases, only visible in certain conditions, such as under ultraviolet light.

Beyond passive information, HP’s technology could allow for the printing of electronics. Using capacitive inks, this would allow for 3D printing of circuits, antennas, and other features. When powered, this could enable RFID, LEDs, Bluetooth and all kinds of other features, that would enable communication and data transfer. Think the Internet of Things (IoT) is cool? How about an Internet of parts?

What’s the Timeline?

HP will begin shipping printers in late 2016 or early 2017. While this might seem like it’s still a way off, making the announcement now gives HP time to ramp up, while giving potential customers time to consider use cases for the technology and make plans for acquisition. When you’re digitizing production, or moving from one solution to another, there’s a lot of work that goes into people and process. Now that they’ve had an opportunity to see HP’s solution, companies can be thinking about who would use its capabilities, how they’ll configure their workflow, and where they’ll locate the equipment, among other considerations.

For service bureaus and internal customers, it also provides enough time to build the business case. They must do their due diligence around TCO, identifying as many variables as possible that are likely to impact their cost and profitability. If the relatively short amount of time is spent wisely, they should have a solid plan in place by the time the machines are ready for order.

And then the fun really begins, assuming HP can deliver on its end of the bargain. Given their 30 plus year history of executing on a global scale, I for one believe they will.

_________________________________

John Hauer is the Founder and CEO of Get3DSmart, a consulting practice which helps large companies understand and capitalize on opportunities with 3D printing. Prior to that, John co-Founded and served as the CEO of 3DLT. The company worked with retailers and their suppliers, helping them sell 3D printable products, online and in-store.

John’s original content has been featured on TechCrunch, QZ.com, Techfaster.com, 3DPrint.com and Inside3DP.com, among others. Follow him on Twitter at @Get3DJohn