In 3D printing, there are four places to make a play. Whether you’re a startup, an existing company looking to enter the space, or an investor with a taste for megatrends, you’ve got to decide where you’ll expend your energy. While it is possible to be in all four, I don’t typically recommend it. Often you end up spreading yourself too thin, or in some cases, even competing with your own customers.

At this point, you can apply a 3D printing strategy in nearly any vertical market. Companies are already demonstrating success in automotive, aerospace, medical, consumer products, engineering, construction, and many others. And we’re not just talking about prototyping anymore. Some large, global organizations are looking at how additive manufacturing can help them digitize entire production and supply chains.

So for the purposes of this article, let’s take a look at the four pillars of opportunity and apply them to a specific vertical. Based on the title, you’re probably guessing education. If so, you passed the test!

HARDWARE

This is one of the toughest entry points. They call it hardware because it’s hard! There are several steps in the product development lifecycle, from innovation and design, to testing, production, and release. You may have a great idea, but you’ve got to work all the way through until it’s sellable and scalable.

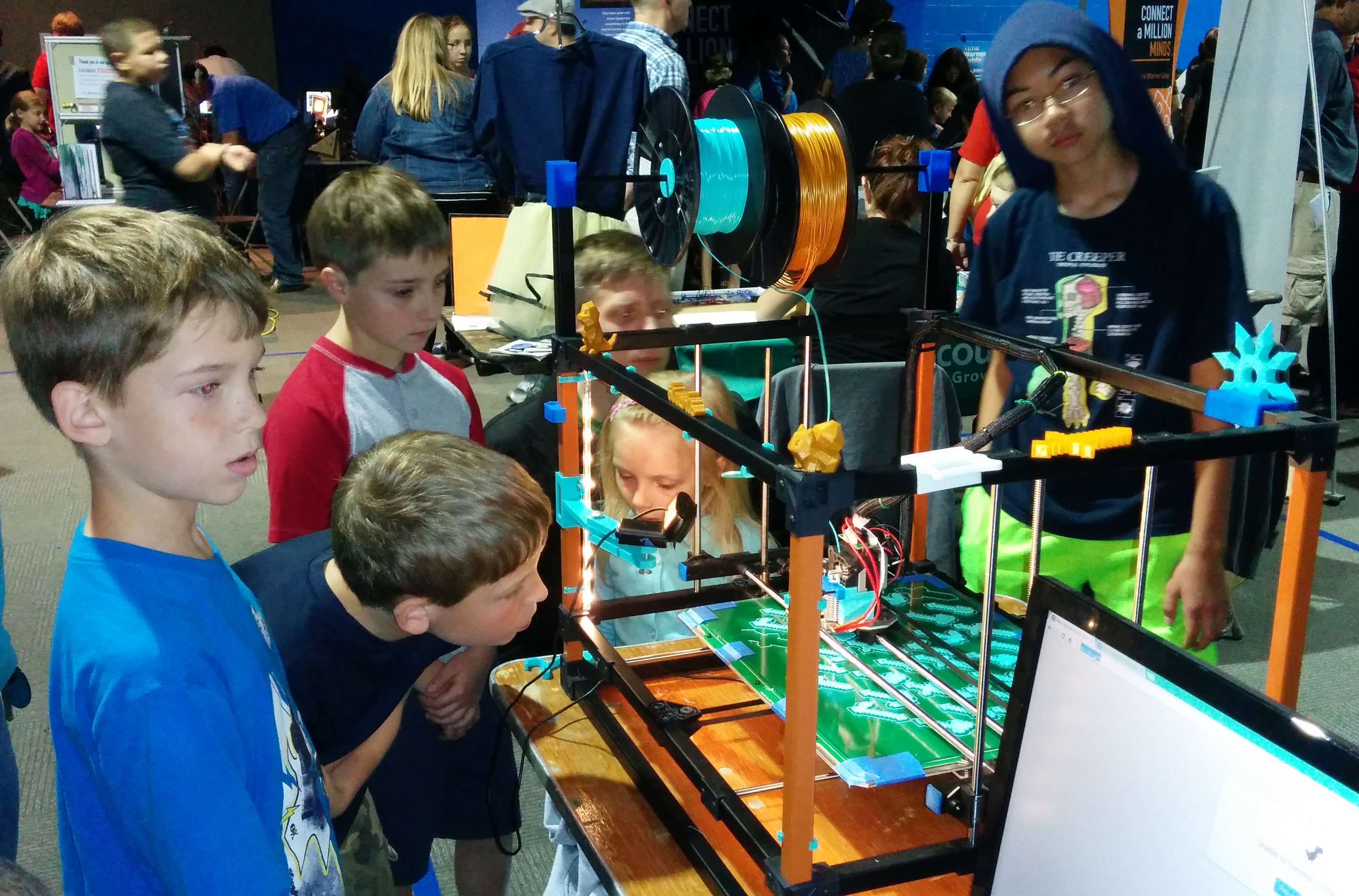

In the educational space there are all kinds of hardware concerns and opportunities. I conducted research with a group of over 4,600 consumers and one of the things they thought was so exciting about 3D printing was “the ability to watch their products being made, either online or in-store.” Classrooms are no different. Anywhere there are kids and a 3D printer is running, you’ll find them pressed up against it, watching products materialize out of thin air.

For this reason most elementary and high (el-hi) schools are taking a decentralized approach. They’re trying to put smaller printers in many classrooms. This can have unintended consequences. Organizations end up with assets littered across their domain, many in non-working condition.

If history is any guide, I wouldn’t be surprised if schools begin to look at a more centralized approach. They’ll weigh the cost and risks of administering a large network of printers. Instead of printing in each class (and managing all the infrastructure that goes along with it) they’ll instead build larger 3D print labs that can handle the capacity of an entire building or even an entire district. As better technology makes that more feasible, it creates new threats and opportunities for the hardware manufacturers competing for those dollars.

MATERIALS

As 3D printing continues to proliferate in schools, it also creates some potential safety hazards. The first is heat. If we’re talking FDM (and most printers in most schools are), you’ve got an extruder melting plastic at high temperatures.

The second safety issue relates to air quality. There have been studies which suggest that carcinogens and other ultrafine particles can be released into the environment when certain plastics are melted in 3D printers. Schools are becoming more aware of this and are starting to invest in enclosures that protect students from heat while filtering the fumes released during extrusion.

While it’s not a huge concern yet, companies that want to develop and sell 3D printable materials into educational environments can create a competitive advantage by minimizing toxicity.

SOFTWARE

There are so many areas of opportunity with software. From how 3D models are created or sourced, to how they’re prepared for printing, there’s room for improvement. But beyond that, software can be used as part of the educational process, helping teachers create lesson plans and collaborate with their students.

One of the areas in which I’m particularly interested is workflow. As mentioned above, I think schools will soon take less of an ad hoc approach, becoming more sophisticated in how they manage the demand for 3D printing.

As I discussed in a previous article, there is a significant opportunity for Web to 3D Print (W23DP) software – both as a way to manage consumer orders and to manage requests from large groups of internal customers. In other related industries, these software solutions not only allow users to submit files, but also give them a way to provide the specifications necessary for cost calculation, which allows service bureaus to quote prices and take orders online.

SERVICES

To some degree software and services go hand-in-hand. If you’re going to offer content for example, you’ve got to have a way to deploy it. Content means different things to different people. In traditional classroom environments, that might mean a formal curriculum. Other settings, like after-school clubs and summer or day camps, might require a quicker, more compressed learning plan. It could also include tutorials on ancillary, but related, topics like CAD design. But, as mentioned above, content could also include a library of print-ready files. In any of those scenarios, users need a way to access and retrieve the necessary assets.

Services also include things like production. In a decentralized environment, it could be as simple as a print queue. But even there, a more holistic software solution could help administrators monitor an entire network of print devices. In a more centralized structure, software could help internal print shops manage the volume, allowing them to forecast and plan their labor, allocate machine time, and optimize their material and supply requisitions.

In the educational market, there is clearly a place for all four pillars. The demand is already present and growing rapidly. From small private academies to large metropolitan school districts and from community colleges to some of the world’s largest universities, educators are recognizing the value of 3D printing and how it fits with other science, technology, engineering and math (STEM) initiatives.

The challenge for companies that are already in the space, and those contemplating an entry, is deciding which of the four to provide. That requires careful thought and deliberation. You need a detailed go-to market strategy. Once the decisions are made and your plan is in place, it’s all about execution.

READ THE ENTIRE ARTICLE AT 3DPRINT.COM

____________________________________________________________________

[3 x 3D = Awesomeness is Copyright © 2015 by Kevin Jarrett]