The go-to-market strategy for most consumer products is pretty common. A concept is developed, then it is mass manufactured and sold through a variety of retail outlets. Along the way, businesses make all kinds of investments in R&D, packaging, marketing, and logistics to ensure the product is successful.

In the consumer packaged goods industry, and with food in particular, the challenge is exacerbated. Products are typically perishable and often more susceptible to damage from poor handling and environmental extremes. As a result, companies in the packaged food industry spend an inordinate amount of money to ensure the product that reaches the shelf meets customers expectations.

Beyond that, brands must also deal with new supply chain paradigms. In the old days, a retailer would place an order, receive a shipment and pay the bill. Today, more and more products are being sold on consignment, and manufacturers are taking responsibility for inventory and spoilage.

But what if those challenges began to disappear?

Consider the music business for a moment. Beginning with Thomas Edison’s invention of the phonograph in 1877, records and later 8 tracks, cassettes and CD’s were sold to consumers. They were a physical product, stocked on brick-and-mortar shelves. Big name retailers like Sears, Kmart and others all sold music to consumers everywhere.

In 2001, Apple launched its first iPod. With it and other MP3 players, customers had the ability to play digital versions of their favorite songs. Over the years, the demand for CD’s and records dwindled to the point where many retailers simply stopped selling them.

Like so often over the last 20 years, retailers were slow to adapt. Some, like Walmart attempted to build their own music streaming services. But they were late to the game and eventually their services were shuttered.

Everyone saw the shift coming, yet few were able to benefit.

The music industry wasn’t alone. Similar disruptions happened in photography, print and other industries.

Could digitization also impact the food industry?

Believe it or not, 3D printing is a 35 year old business. For most of that time it was a cottage industry, used to make prototypes. But, over the last 10 years that began to change. The technology got better, faster, and cheaper. As a result people started thinking outside the box. They began asking whether it could change the way finished products are made.

On the industrial side, innovators began using the technology to make complex parts that couldn’t be produced any other way. For example, starting in the early 2000’s GE began working on 3D printing parts for their jet engines. In 2015, one of their designs became the first 3D printed part to be cleared by the FAA, and GE began installing them on commercial airplanes.

In the consumer world, companies began looking at how 3D printing could help with customization and personalization. The hearing aid industry was a great example. To improve the experience for users, they wanted to create products that conformed to specific person’s ear. 3D printing allowed them to meet the demand and within 500 days, the entire industry went digital. Now nearly all hearing aids are 3D printed.

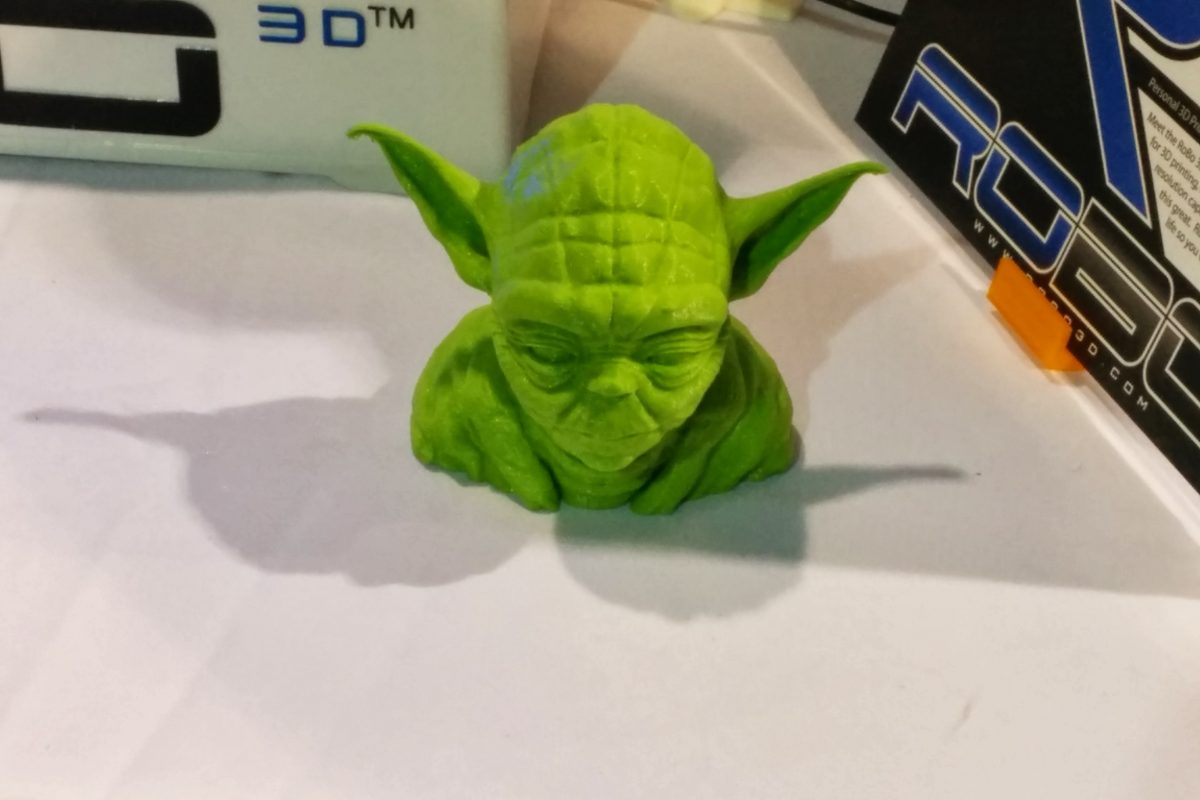

Soon other customized and personalized products followed. Today everything from prosthetics, orthotics and shoes, to invisible retainers, mascara brushes and razor handles are being 3D printed and sold to consumers as finished products.

But, what about the food industry?

Like every emerging technology, 3D printing went through a hype cycle. Earlier in the decade, desktop 3D printers began arriving on the market. Without a thorough understanding of how the machines worked, many assumed that soon everyone would have a 3D printer in their home or office and would use it to make nearly anything they desired. They envisioned a Star Trek replicator. The reality was no where close.

The hype extended into food. Several companies announced ambitious plans to create 3D printers that could make edible products. People saw demonstrations of 3D printers making everything from candy to pizza and assumed that in the near future, everyone would have one in their kitchen. Again they were wrong.

That’s not to suggest that 3D printing won’t impact the food industry. It will. Brands and retailers have an opportunity to use 3D printing to change how their products are designed, produced, packaged and delivered to consumers.

3D printing offers unique advantages

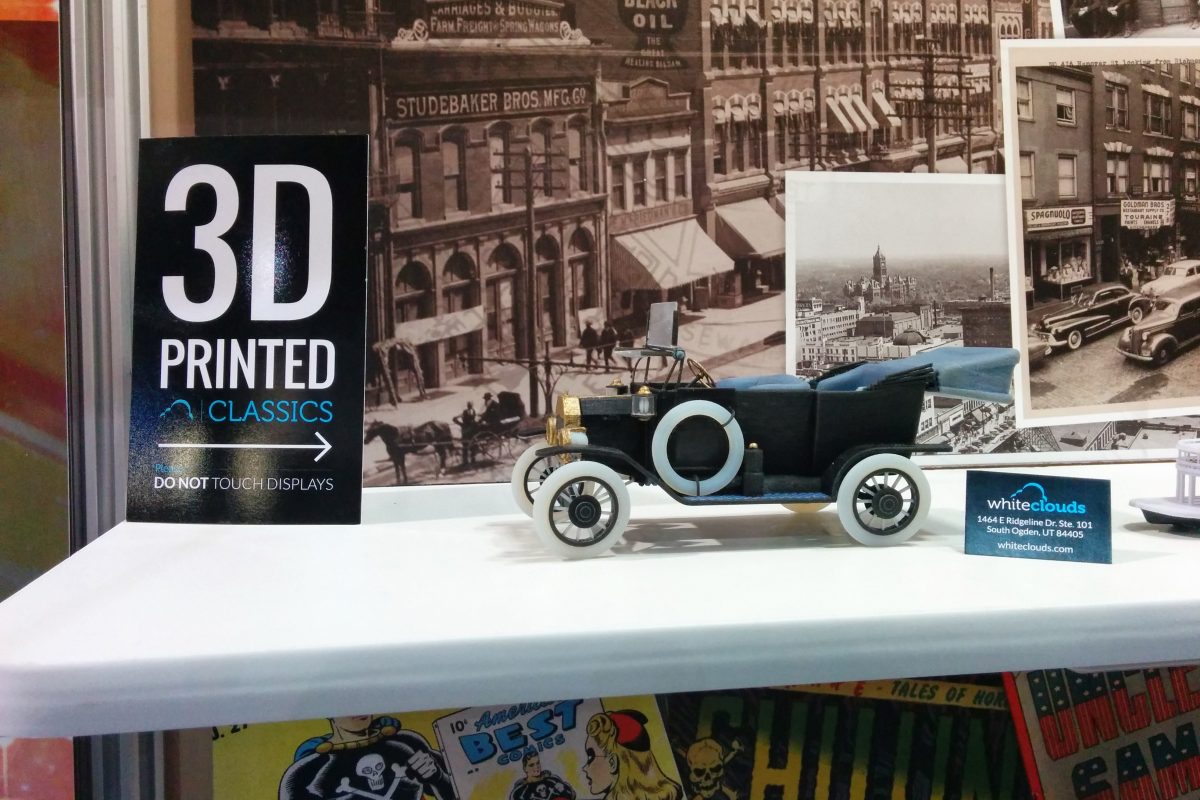

To some degree it starts with a thorough understanding of the benefits. As mentioned above, 3D printing can be used to make products that can’t be made any other way. This could not only allow brands to change the shape and texture of food products, but also allow them to develop innovative new packaging. Further, customization and personalization could allow them to vary their products for individual needs.

3D printing can also go much further. The economics are such that small batch production becomes much more affordable. This could allow brands to develop profitable products for very small, niche markets. Also because it’s digital, 3D printing offers a speed-to-market advantage other manufacturing processes can’t match. This could allow brands to outpace their competition and take advantage of trends as they emerge.

Where and how will 3D printed products be made?

When it comes to implementation, the industry has some big questions it must answer. One of the first is, “where will 3D printed consumer products be made?” At this point we can safely assume that most products won’t be made by individuals in their homes. It’s possible that they could be made in a factory like mass produced things are made now, but that ignores one of 3D printing’s greatest strengths. Because it begins with a digital file, the technology has the potential to upend traditional supply chains. After all, it’s much cheaper to ship data than it is physical goods.

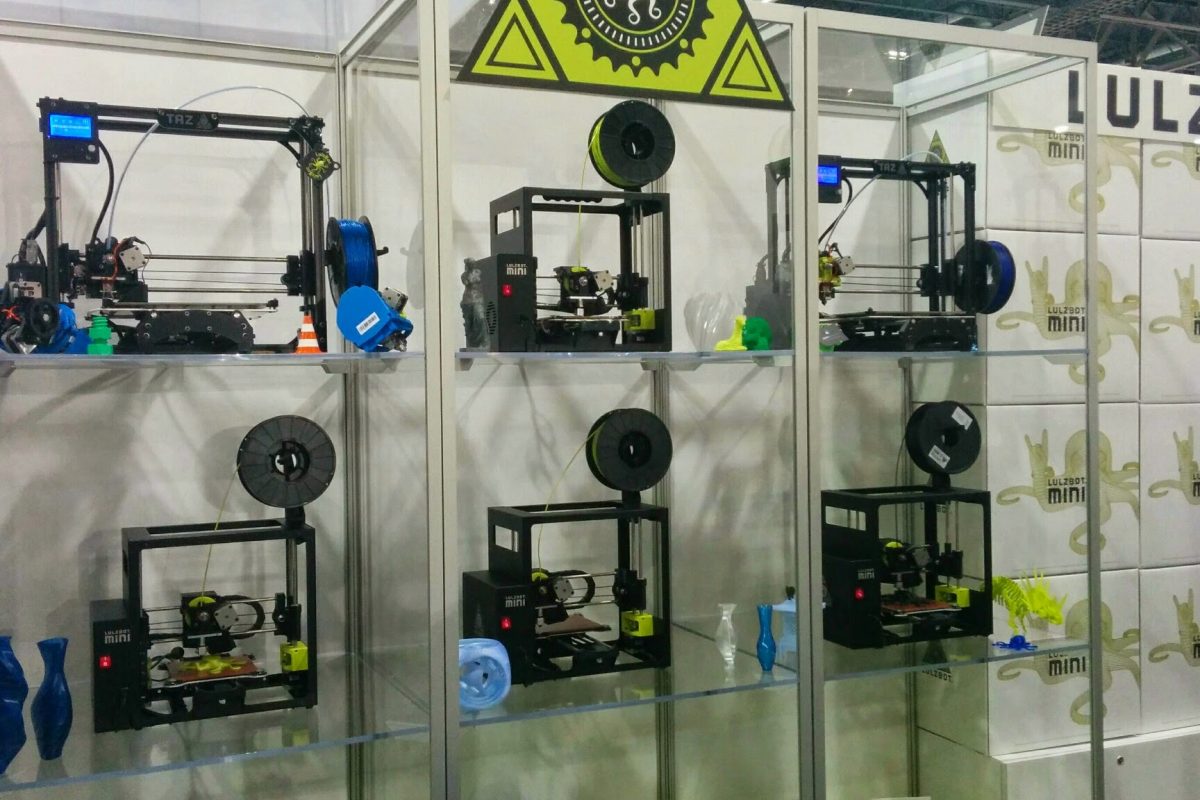

So if not in the home, then where? The easy answer is, as close as possible to the end consumer. Which leads to the next question, which is “who will make them?” One could make a strong argument that retailers are a natural fit. They are the ones who stock and sell the mass produced products we all use every day. In theory, a super store like Walmart could have a 3D printer in every aisle. One in housewares making kitchen utensils, another in sporting goods making fishing lures and golf tees, and yet another in the bakery making candy and chocolate.

But that will require significant investment in infrastructure. Putting 3D printers in thousands of stores won’t be cheap. It will also require retailers to work closely with brand partners who own the content – digitally printable things.

What’s the Return on Investment?

A few years ago McKinsey predicted that eventually 5-10% of all consumers products (in relevant categories) would eventually be 3D printed. The average Walmart has 500,000 SKU’s in store. Amazon provides over 500 million. If 5% of those were 3D printable, a brick-and-mortar store could offer an additional 25 million products with very little incremental cost.

Perhaps more importantly, can you think of another technology over the last 20 years that was actually a benefit to brick-and-mortar? eCommerce certainly wasn’t. Mobile hasn’t been either. But 3D printing could actually put physical retailers in a better position than their online rivals. Not only would customers come to purchase products that could be manufactured on demand, but based on convenience, they’d also fill their baskets with mass produced items and make other impulse purchases.

For these reasons alone, retailers and consumer packaged goods companies must give 3D printing serious consideration. But beyond new sales opportunities and the ability to defend against disruption, the technology could also help them provide a better experience. Nearly everywhere 3D printing is displayed, people are pressed up against the glass, watching products being made before their very eyes. In an era where online shopping can often be more convenient, retailers must provide a more engaging environment. 3D printing can assist them in providing it.

This article originally appeared in Candy & Snack Today