With all the business interest in 3D printing, the demand for service bureau work is increasing. Many will soon experience growing pains. To fully capitalize on their opportunity, service bureaus and others who provide 3D printing services will need to automate their workflow – especially with front end activities like quoting, order entry, and customer service.

I’ve seen estimates which suggest that globally, there may be more than 1,200 3D printing service bureaus. Some even say as many as 5,000. I’m not sure how accurate those numbers are, because they’re probably lumping makerspaces, fab labs and in-plant shops into that mix.

An “in-plant” is a term used to describe a 2D print shop that’s owned by a company (or other institution) and services internal customers. I haven’t heard a better term to describe them for 3D, so I’ll borrow the term for the purposes of this article.

These diverse types of facilities all have customers. With service bureaus, those customers are external. In other cases, most or all of those customers are internal.

Some of the work from those customers is predictable. In an educational environment, the work submitted by students is typically assigned. This can be helpful in a couple of ways. First, it can make things easier from a prep standpoint. The files are often standardized and reviewed by teachers or others before they’re submitted for printing. Second, the volume of work can be planned. You can accurately forecast how many orders you’ll receive over the course of a semester, for example.

In an industrial setting, things are a little more fluid, but you can still exert some control. Companies can define software tools and put standards in place for how files should be created and submitted to an internal shop. In addition, they can apply budgetary constraints and require staff to forecast their needs. Often this only happens once demand grows to the point of being painful, but when inefficiencies are recognized, things tend to get resolved quickly.

Drinking From a Fire Hose

Control is a luxury most service bureaus don’t have. When they’re ramping up, they typically endure periods of feast and famine. They go out and sell their service, get busy, stop selling and then run out of work. Depending on the markets they serve, this can get magnified by seasonality in their business. Retailers for example, tend to be busiest prior to the holidays.

If a service bureau is able to survive the startup phase, or gets lucky and falls into the right markets, volume builds. At that point it can be like drinking from a fire hose. Work comes at them from many different directions and it all has to be processed, produced and shipped.

Compounding this problem is the fact that the industry is moving from prototyping into production. Prototypes are high margin orders. With 3D printing, production is typically lower volume and requires quick turn. This creates a lot of small orders instead of fewer bigger orders. As I’ve mentioned before, the transaction cost that goes along with each order is fixed. It can cost the same amount of money to move a $50 order through your facility as it does a $5,000 order.

History Repeats

I’m sure that sometimes I seem like a broken record when I write about this, but print shops in the 2D industry dealt with many of the same problems. To remain competitive, they needed to become more efficient to handle the growing volume of smaller orders and they also had to drive transaction cost out of their businesses.

Labor is finite. There is only so much each person can do. As the number of monthly orders continued to rise, shops were forced to hire more people to manage them. But most of the time they’d lag behind the curve. They’d only add another body when backs were ready to break. The customer service manager would go to the owner and let them know of an impending mutiny. Eventually the owner would authorize another hire.

Then, when the natural ebbs and flows of business hit, the layoffs would start. If a company lost a big customer, several people might be impacted.

The Ah-Ha Moment

I’m telling you now that the same thing is likely to happen with 3D printing. Service bureaus will decide that it’s cheaper to solve workflow problems with labor than it is with technology. This will hamper their growth and create a lot of overworked, stressed out employees. Things will get even worse when they hit a lull.

The problem will eventually become so acute that companies will finally decide to act. They will start by trying to define the problem. Sometimes this goes well and other times it gets ugly, like when everybody describes the problem differently and blame gets tossed around. Sooner or later though, they will figure it out. They’ll have the proverbial “ah-ha” moment when the problem becomes obvious:

“Our workflow is so constrained that it’s causing customer and employee dissatisfaction, in addition to hampering our growth.”

Technology Is Always The Answer

With the problem defined, they can finally begin work on a solution. Technology becomes the logical answer. In today’s software-as-a-service (SAAS) enabled world, one would assume there’s ready-made solution for this problem.

20 years ago in 2D printing, that wasn’t the case. Companies had to make a build or buy decision. Some would try to license software and tailor it to fit their needs, while others would build their own solution, in-house.

Today it seems SAAS is everywhere. Want CRM? Sign up for Salesforce. Need marketing automation? Choose between Hubspot, Marketo, Pardot or a host of others.

But 3D printing is more like 2D printing was back then. Until recently, the industry was so small that no one was really focused on workflow. If companies wanted it, they had to build their own workflow tools. Service bureaus, universities, in-plant shops and others cobbled together whatever tools they could to allow their customers to upload files, get quotes and submit orders. Some of it was pretty slick. Others, not so much.

Web-To-3D Print Software

As the 3D printing industry has grown, entrepreneurs and larger companies have gone beyond machines and materials. They’re finally creating software that improves productivity by automating workflow.

Web-to-3D print (W23DP) software is available to help companies manage estimating, order entry and a host of other tasks.

The implications can be profound. In a university setting, W23DP software can allow fab labs to manage the large influx of jobs they receive at the end of each semester. In an internal center, it can allow companies to better handle key points in the product development lifecycle. For service bureaus it can allow them to scale up their capacity and better plan future investments in hardware.

But for all of these organizations, there’s also a hidden benefit. Modern W23DP systems offer application programming interfaces (API’s) that allow software solutions to talk with one another.

But for all of these organizations, there’s also a hidden benefit. Modern W23DP systems offer application programming interfaces (API’s) that allow software solutions to talk with one another.

API’s can be used in myriad different ways. They can help companies collaborate in real time. API’s can also help organizations effectively load balance between their internal capabilities and outsourcing. Perhaps most importantly, they can also give businesses access to data they’ve never had before, allowing them to effectively track and manage activity and spend across the enterprise, whether work is produced in-house or outside.

This type of 360 degree, holistic view of the organization is the stuff of executive wet dreams. Especially when they realize the kind of money they’re spending on 3D printing now and likely to spend in the future.

Why DigiFabster?

Prior to getting into the 3D printing market, I spent much of my career designing, selling and implementing web-to-print solutions for the 2D printing industry. I’ve learned a lot about what works and what doesn’t. Now I’m applying that knowledge in 3D.

I’ve conducted exhaustive research to find the best possible solution for automating front-end workflows. In my humble opinion, DigiFabster solves the problem in ways no one else can. The basic solution enables online quoting, order entry and customer management tools. The software also features a robust API that enables communication and reporting.

Further, the team at DigiFabster understands the importance of being able to customize the software to meet specific client needs. They’re skilled at integration and they know how to move fast without breaking things.

Get3DSmart’s partnership with DigiFabster provides even more value for clients who are dealing with antiquated, manual workflows. Together we have the knowledge, skills and ability to help companies quickly become more efficient, while greatly reducing the soft costs that frequently hamper growth. That’s a win-win-win.

To learn more, check out our recent press release, or CONTACT US today.

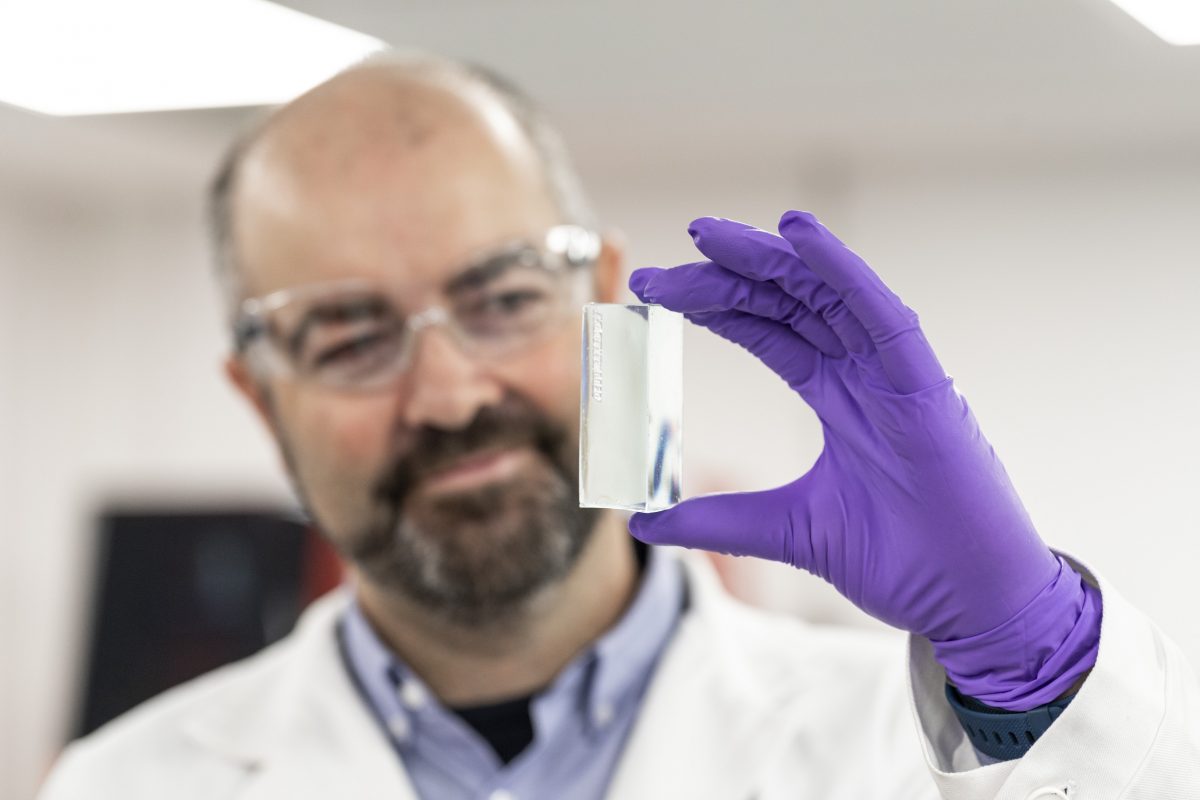

Image credit: Naval Surface Warriors | Copyright 2017