In 2012 I co-founded a startup that helped retailers sell 3D printed products. There were six other co-founders. When we went looking for venture capital, many potential investors told us there were too many people on our cap table. They said ideally, a startup should have three founders, the hacker, the hipster, and the huckster.

What they meant is that successful startups (especially in software) typically have someone who builds the product, someone who sells it, and someone who operates the business. It creates clean lines of responsibility while also ensuring that everything that needs to get managed, does. Having fewer founders increases the workload, and having more just creates chaos.

That advice stuck with me. I swore that the next time I founded a startup, I’d build a team of three with diverse, yet complementary skill sets.

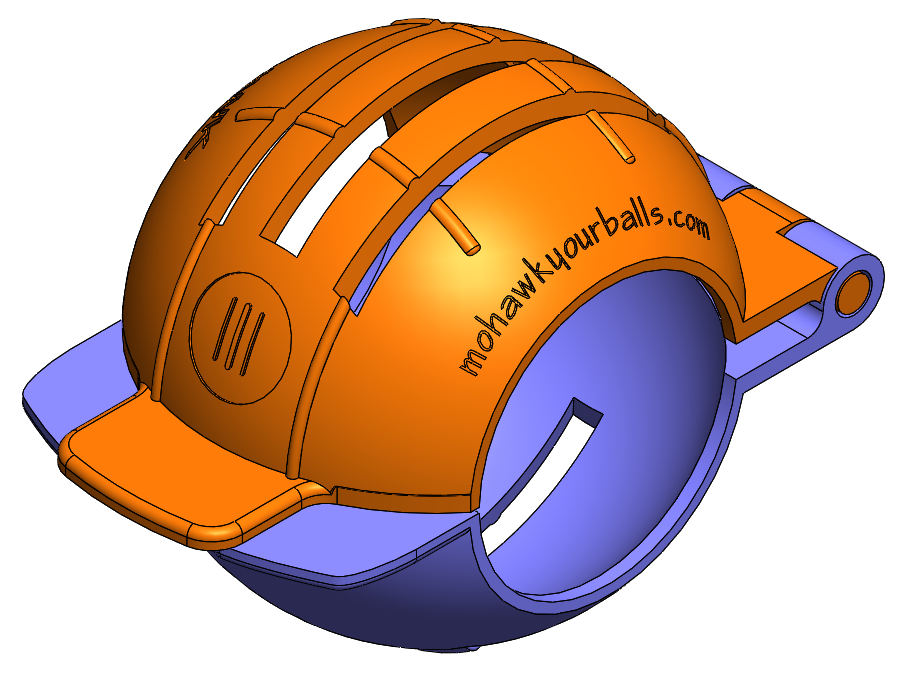

About five months ago, I had an idea for an innovative new product for the golfing industry. I’d been reading about the Vernier Acuity principle, and how golf equipment companies were using it to help players improve their putting accuracy. I wanted to develop a stenciling product that would allow players to draw three lines on their golf ball.

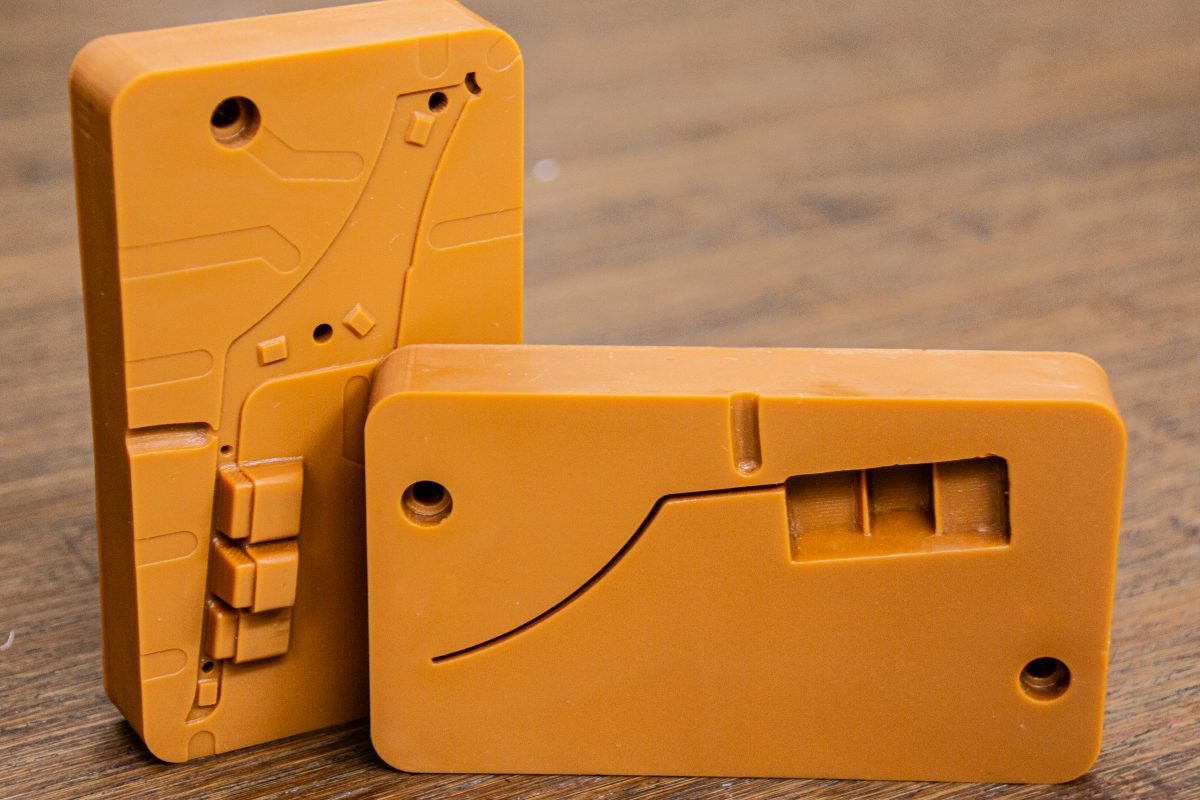

I have worked with several industrial designers throughout my career, but one of the best was Craig Garoutte. He worked for our previous startup and demonstrated an amazing ability to transform ideas into tangible things. Since I envisioned 3D printing the product, it also helped that he has a thorough understanding of the technology.

In my head, I saw this as the first of many products we could develop. Over the past few years, 3D printing (AKA additive manufacturing) has changed dramatically. Quality, capability, and productivity have greatly increased while costs have dropped significantly. This enables all kinds of benefits including; design freedom (parts can be made in ways they can’t with traditional manufacturing techniques), on-demand and just-in-time production, customization, and perhaps most importantly, speed-to-market.

I wanted to take advantage of all of them, enabling a company that could take new products to market faster and less expensively than anybody else.

You see, there’s a major barrier to innovation in product development. It’s estimated that only one idea out of 1,000 ever becomes a product, and of those that do, 2% actually become successful. That’s a startling .002% success rate.

The primary reasons are risk and lack of capital. Mass manufacturing is an expensive proposition. I can’t tell you how many times I’ve shared the costs of 3D printing a new product with someone and they’ve said, “What? You can make those for a dollar in China!” No, you can’t. You can make 10,000 for $10,000 in China.

3D printing destroys those barriers and opens the flood gates to innovation. But, I also knew from my previous experience that protecting intellectual property, especially in digital form, can be challenging. Our fledgling new firm would need someone to manage it.

It just so happens that my primary golfing buddy, Dustin Lehmann loved the idea. He’s a former Army Ranger and an attorney. So I asked him to be our third co-Founder. Not only does he manage our intellectual property needs, including patent, trademark and copyright protection, he also understands how to operate a business.

So with Craig as our hacker and Dustin as our hipster (he hates that term, LOL), and me obviously as the huckster, we were ready to get to work.

Over the next four months, we founded CDJ Designs and began developing our first product. We created several prototypes and field-tested the living hell out of them. By late-June we knew we had a market-ready product. Over the last month, we worked out the branding, packaging and go-to-market strategy for our new device.

On August 9, we go live with the Mohawk 3D Golf Aligner. It’s a patent-pending, 3D printed stenciling device that helps golfers putt up to 15% more accurately. It’s also Made in the USA by a Veteran owned company (thanks for your service Dustin!)

We are bringing the product to market with an investment of less than $1,500. In part that’s because we were able to utilize a lot of our own sweat labor. But also it’s because we’re manufacturing the product and packaging “on-demand,” and have very little of the upfront cost and risk that are typically associated with traditional manufacturing.

Now the fun part starts. I get to do my job as the huckster and go sell this baby. That’s always more exciting when you believe in your product. I know we’ve built a better mousetrap and I can’t wait to tell the whole world about it.

In the background though, we are already hard at work ideating and developing other innovative new products. We’re moving fast and breaking things and that feels so good. I consider myself lucky to be part of such an amazing team and look forward to our inevitable success.

See you at the top!

To learn more about the Mohawk 3D Golf Aligner and sign up for our early access offer, please visit MohawkYourBalls.com