IN FOCUS: Sustainability in Additive Manufacturing

Guest post contributed by Cindy Deekitwong, Henkel Corporation

While recycling efforts are making headway, there is still much work to be done. Many countries collect and recycle waste improperly and people in many places are unaware of the impact their waste has on the environment. At the same time, most types of plastic take hundreds of years to biodegrade.

It is clear that a solution to the problem of plastic waste is only possible when stakeholders along the value chain work together. By fostering a circular economy and developing sustainable packaging solutions, Henkel wants to make a positive contribution.

Henkel’s Sustainability Strategy

By 2030, Henkel’s overall goal is to triple the value we create through our business activities in relation to our environmental footprint. To achieve this goal, we’ve integrated environmental responsibility into our innovation process, so that each new product or formula we launch has a positive impact on sustainability.

Alongside this focus on innovation, we’ve set ambitious targets for ourselves as part of a comprehensive sustainability strategy. This provides a shared understanding of our direction of travel by building sustainability into the day-to-day work of our employees around the world. It also drives progress toward improved sustainability and business performance – because we believe these two aspects go hand-in-hand. Together with our partners, we’re advancing sustainability along the entire value chain.

Henkel’s sustainability efforts are also being recognized by external partners and customers.

Sustainable Solutions for 3D Printing Operations

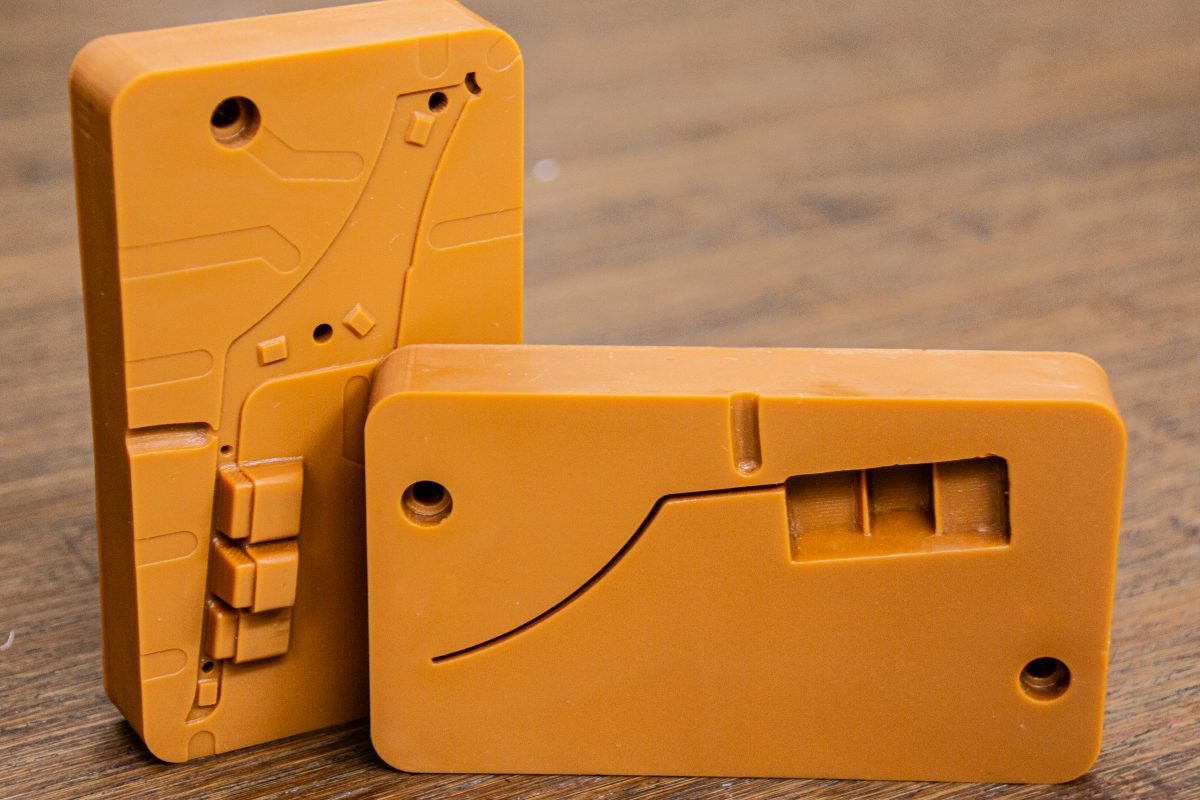

One area where this is evident is in our new 3D printing business. Shortly after launch, we announced a partnership with TerraCycle, and together became the first organization worldwide to offer a recycling solution for anaerobic and light cure adhesive packaging. Through this program, Henkel’s customers with 3D printing operations are provided with a recycling box where used containers of UV curable 3D resins and cyanoacrylate-based adhesives are placed and later recycled by TerraCycle.

One area where this is evident is in our new 3D printing business. Shortly after launch, we announced a partnership with TerraCycle, and together became the first organization worldwide to offer a recycling solution for anaerobic and light cure adhesive packaging. Through this program, Henkel’s customers with 3D printing operations are provided with a recycling box where used containers of UV curable 3D resins and cyanoacrylate-based adhesives are placed and later recycled by TerraCycle.

“Our goal is to be the customers’ champion for all industrial additive manufacturing solutions, and through our partnership with TerraCycle, we also make sustainability simpler for our customers,” says Philipp Loosen, Global Head of 3D Printing, Henkel Adhesives Technologies. “As a company with a strong commitment to sustainability and innovation, we are pleased to offer an environmental solution to customers who share our corporate values and use our adhesive products to spur innovation and transform the future of industrial manufacturing.”

By definition, additive manufacturing offers some sustainability advantages. Material is added instead of subtracted, reducing or eliminating much of the waste created by other methods. But it also enables on demand and short run production, encouraging users to make only what is needed, instead of buying more to pay less, knowing very well that some portion of what is manufactured may eventually be scrapped.

A few months ago, Henkel acquired Molecule Corp. They were well-known as an innovator in the additive manufacturing materials space, focusing specifically on resins and solvents associated with stereolithography (SLA) and DLP 3D printing. Molecule had a deep understanding of the sustainability issues in this industry and Henkel’s commitment to solving them was a deciding factor.

“A comprehensive sustainability program must focus on all three “R’s”; reduce, reuse and recycle,” says Molecule’s Founder, Ken Kisner. “3D printing already offers sustainability advantages by the nature of how it works, reducing the amount of material used. But, there are additional opportunities for improvement,” One of those is the reusability of solvents. We’re working to design materials and systems that promote reuse. Further, in those instances where reduction and reuse aren’t possible, recycling is key. Through the partnership with TerraCycle, it’s an area where Henkel has become a first mover.”

Henkel’s sustainability efforts are also being recognized by external partners and customers.

“Often 3D printing is about convenience and speed; two things that can be at odds with long term sustainable practices,” says Dan Straka, General Manager at InterPRO. “In the service bureau business, there is a lot of pressure to go fast, and speed often incurs waste for the sake of meeting a deadline. Programs like Henkel’s recycling program encourage InterPRO’s growing eco-mindful team to continue our cultural mantra of protecting; our clients, our team, and to the extent we can with our own resources, the earth.”

Henkel’s sustainability efforts are designed to set an example. All along the value chain, from equipment providers and other materials companies, to service providers and end users, everyone can play a role in helping additive manufacturing live up to its green potential.

In a future article we’ll look at how Henkel is engaging the manufacturers of 3D printing equipment by building sustainability into its new Open Materials network. Stay tuned!