Today at SOLIDWORKS World 2018, HP announced a new series of 3D printers that further expand a portfolio of products that leverage Multi Jet Fusion. In addition to offering two different build sizes, the new Jet Fusion 300 / 500 series give customers the ability to print in black or white, and in full color.

I’ve written a lot about the huge opportunity 3D printing has with full color. I spent the first 20 years of my career working in the 2D printing industry and saw first-hand the monumental influence affordable digital color had on that industry. I believe it will have a similar impact on the 3D printing industry.

Color is too important.

In addition to being decorative, color helps us organize, group and understand information. It simplifies identification and improves safety. Color also enables branding and plays a vital role in sales and marketing. But color can also serve more utilitarian purposes. Color can improve how products are used and maintained. In the world of mass manufacturing, color adds value. Practically anywhere color can be used, it is.

For 3D printing, full color represents an enormous market opportunity.

When HP announced their first 3D printers back in 2016, I wrote an article covering the launch and noted that out of the gate, HP was launching Multi Jet Fusion (MJF) with devices that printed only in black, but making full color commercially available was high on the agenda. I added that with, “2D digital printing, the ability to affordably and quickly print in full color created a “hockey stick moment” for the industry. More than anyone, HP understands that.”

The Announcement

So today HP announced that it would expand its 3D printing portfolio with the goals of:

- Further democratizing 3D printing

- Allowing designers to use the same technology from prototype to production

- Enabling functional parts in black, white, and full color

HP’s new Jet Fusion 300 / 500 series actually includes four new devices. Two of them print only in black and white. The other two print in full color. Build size is the other key differentiator. The smaller machines feature a build area of 7.5 x 9.8 x 10 inches. The larger machines print up to 7.5 x 9.8 x 13.1 inches.

Pricing for the Jet Fusion 300 series starts in the $50,000 range and a fully loaded version can top $100,000. HP expects to begin shipping the new machines later in 2018.

Target Customers

The ideal buyers of these new devices are small to medium-sized product development teams and design businesses, entrepreneurs, universities and research institutions.

With this product launch, HP is further demonstrating its commitment to making 3D printing more accessible. In the press release, HP’s President of 3D Printing, Stephen Nigro said that, “HP is committed to democratizing 3D design and manufacturing, unleashing new possibilities for millions of innovators around the world” and that the new 300 / 500 series gives them, “the freedom to create brilliant new parts liberated from the constraints of traditional production methods.”

More About HP’s New Devices

All of the new printers utilize HP’s Multi Jet Fusion 3D printing technology, which applies agents to change the properties of each voxel. The agents are dispersed onto a bed of powder through print heads which are similar to those used for industrial inkjet printing. They’re then activated using UV light.

The 340 and 540 printers can store and disperse four agents – including black and white, in addition to the fusing and detailing agents used by HP’s other 3D printers. The 380 and 580 printers offer four additional agents, which combine to provide full color.

Unlike the Jet Fusion 3200 and 4200 series printers, which utilize a removable build cart and separate processing station, workflow is contained within one device on the 300 / 500 series. It’s more compact, but can’t compete with the speed of its larger siblings.

HP says that the 300 / 500 series printers are capable of making a full bucket with 52 parts in about 15 hours and as many as 5 parts in around four hours. According to HP, parts are printed “in a fraction of the amount of time” they would take when printed using other methods like material jetting, FDM, and SLA.

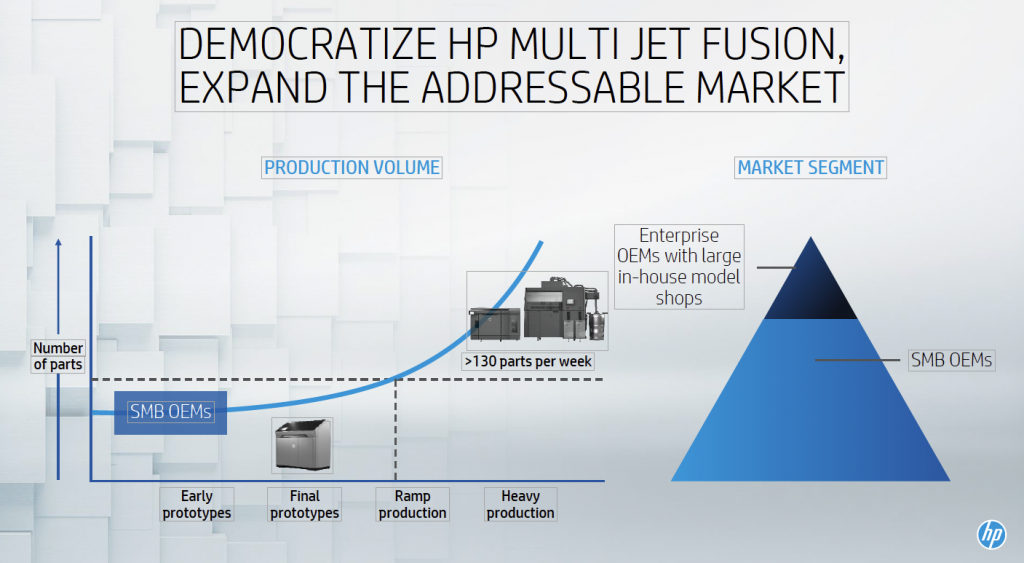

In some ways the devices are complimentary. HP sees the 300 / 500 Series playing a role earlier on the in the product development process, and then later, as a product enters production, migrating to larger MJF machines.

The audiences are also different. As mentioned above, the 300 / 500 series are targeted primarily at small and medium sized businesses. Potential customers for the 3200 / 4200 series are typically larger OEM’s and service bureaus.

Applications for Full Color

So what will these new HP 3D printers actually be making? In my previous articles I’ve talked a lot about consumer products, where applications could include everything from interior decor items to fashion and tech accessories, jewelry, sporting goods, and more. Fishing lures, smartphone and other device cases, and specialty items all immediately come to mind.

My previous company, 3DLT helped launch 3D printing as a product category at Walmart. Our first product was a 3D printed rose.

Each rose was printed in two pieces, in white nylon plastic using SLS. Afterwards they were all hand-dyed to color. Quality was inconsistent and the process was expensive and slow. HP’s technology would be ideal for an application like that.

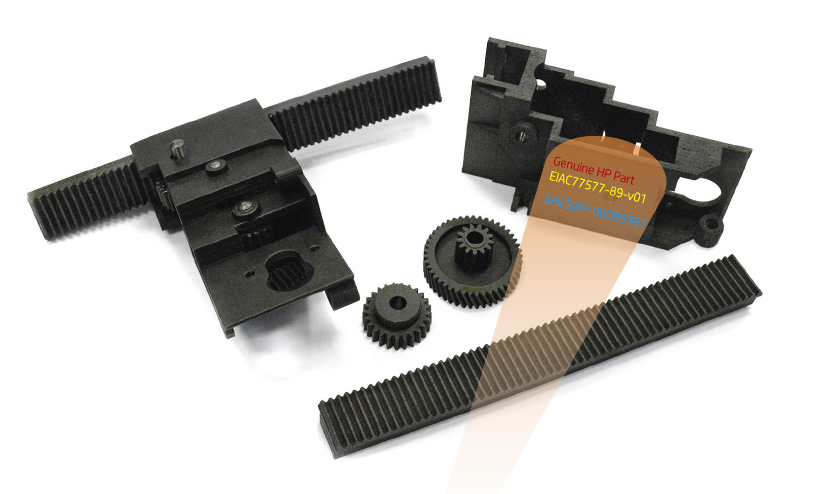

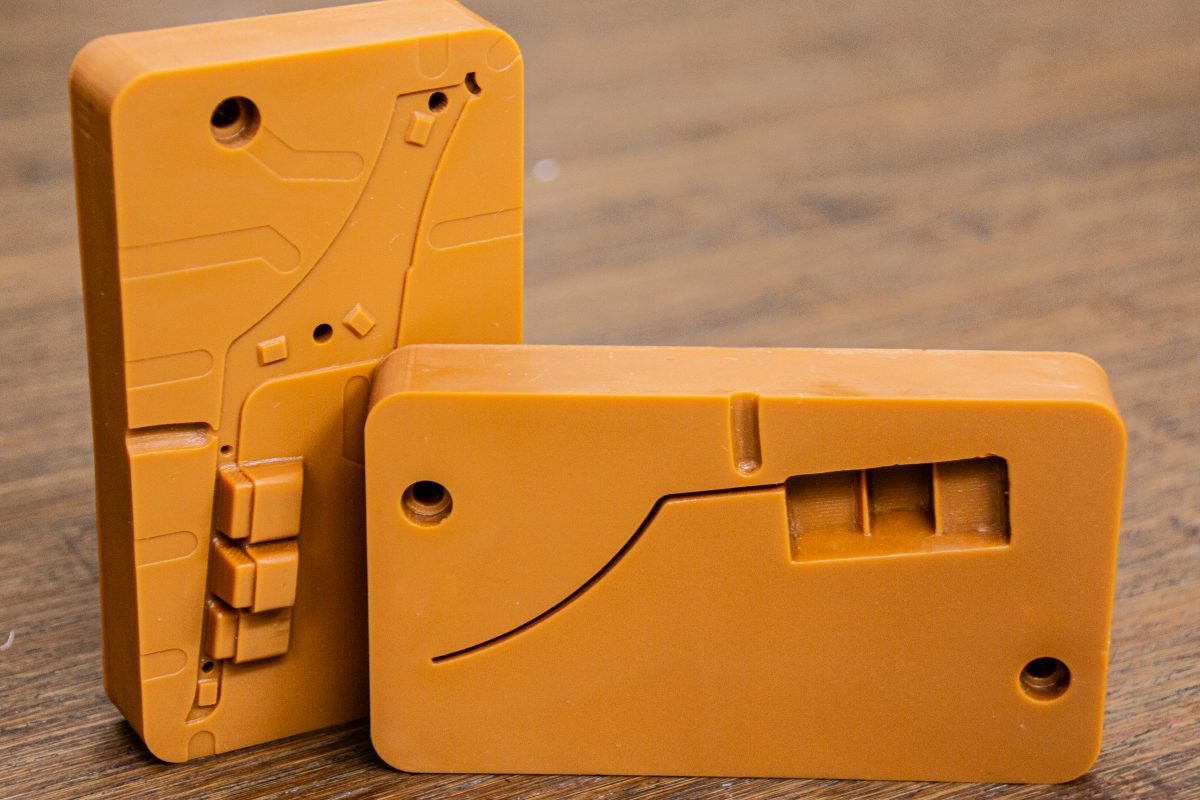

But color’s opportunity doesn’t end with consumer products. There are also plenty of commercial applications. Prototyping makes obvious sense, but color can also play an important role in the design of jigs, guides and other tooling used for mass production.

Further, color can be used for marking and identification.It can even be used to create wear indicators, reducing the cost of maintenance and downtime.

The Big Picture

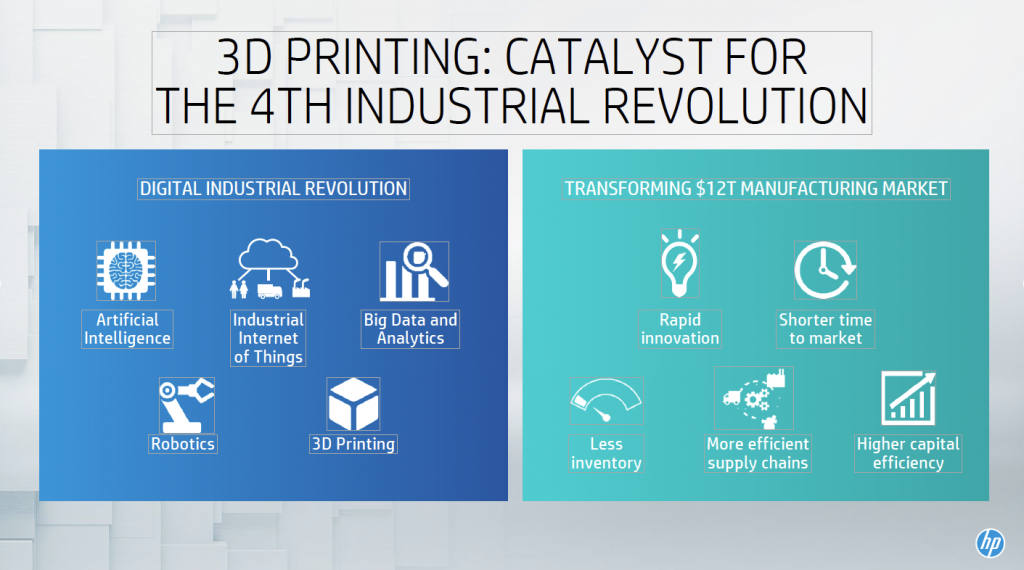

For HP this is part of a broader strategy to disrupt the $12 trillion global manufacturing market. Like many in the industry, they foresee a fourth industrial revolution, driven by digitization. 3D printing will combine with artificial intelligence, the Internet of Things, robotics and other technologies to enable digital manufacturing and smart production.

Read our article about how emerging technologies are combining to change the way we make things.

Solutions driven by these technologies could accelerate the pace of innovation while redefining the concept of a supply chain. Further, they could provide companies with an unrivaled speed-to-market advantage.

Read our article about 3D printing’s big speed-to-market advantage.

At a recent Securities Analyst Meeting, HP announced that it would be introducing full color and metal capabilities. HP Inc. President and CEO Dion Weisler said then that the company was “doubling down” on its commitment to 3D printing.

As HP continues to build out its portfolio, they’ll continue to focus on new applications, driving higher print volumes. Full color opens a lot of opportunities – throughout the product development process – from prototyping into production.

At Get3DSmart, we help our customers identify and capitalize on big opportunities in 3D printing. Color could be one of the biggest yet! Whether its used for decoration, branding or a more utilitarian purpose, color plays an important role in determining how we acquire and use physical products, and we’re finally reaching the point where technology makes it possible to digitally manufacture full color products affordably.

How could full color 3D printing help your business?

Whether you’re looking to develop new products or improve the function and performance of existing products, color can be an important factor. When combined with a digital workflow it could provide an advantage your competition simply can’t match. We can help you get there.

To learn more, CONTACT US TODAY.