iOrthotics supplies orthotics for podiatrists and other medical professionals. The company was founded in Australia in 2009 and later partnered with the University of Queensland to develop its unique solution. Through their efforts, the company has experienced rapid growth, driving employment and energizing their local economy.

In 2017, the company acquired its first HP Multi Jet Fusion 3D printing system. It enabled them to produce custom-made orthotics less expensively and with far less waste than with other traditional manufacturing methods.

The Challenge

With their system in place, iOrthotics began exploring how their processes and technology could serve other markets. The result was a new subsidiary called i3DPS. The goal of the new division was to provide services to clients in other industries, helping iOrthotics maximize their capacity and scale their business.

To outpace their competition and operate efficiently as possible, they knew they’d need to automate much of i3DPS’s front-end workflow.

“A lot of other services use submitted online inquiry forms, and then you have to wait on a sales representative to quote the project and get back to you,” says iOrthotics Founder and General Manager, Dean Hartley. “It can take days alone just to get that quote. Consumers these days want to have instant quoting and make their decision immediately. If they’re happy with the offer they want to be able to place their order without any roadblocks or time delays. We were determined to meet those needs.”

The Solution

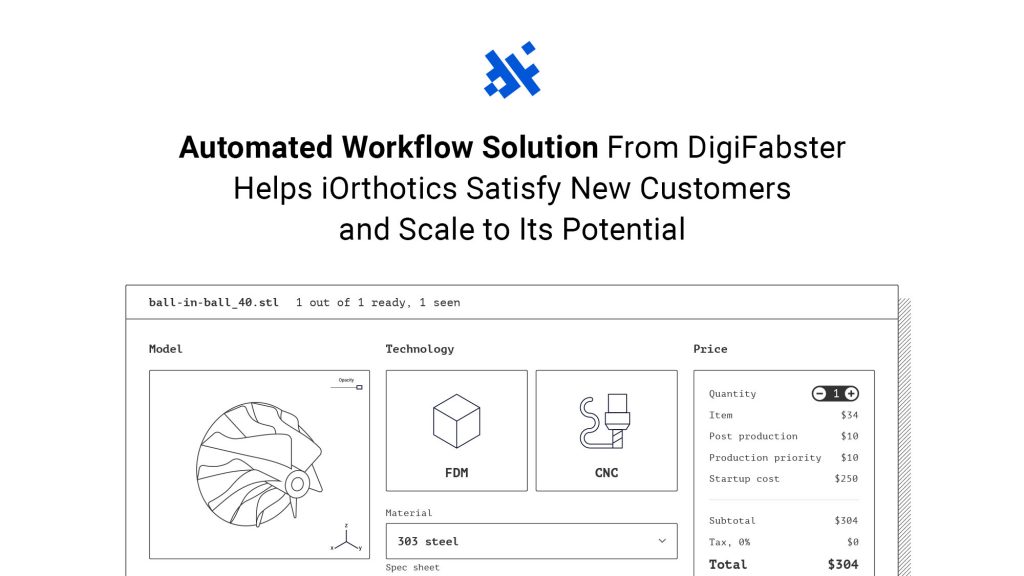

To accomplish their goals, i3DPS chose DigiFabster’s industry leading front-end workflow software solution. It allows them to automate common tasks like quoting, order entry and project management. As a result, it also helped them reduce much of the time and labor that goes along with those activities.

“Before we had DigiFabster on i3DPS it was difficult for us to do quoting and track and manage orders,” said Mr. Hartley. “It did hold the business back, so putting a system like this onto our website that not only offers quoting tools, but also provides status updates for customers, and automates payment actually has allowed us to scale our business significantly. It even acts as a CRM solution, and that in itself is worth its weight in gold.”

As a result, iOrthotics is achieving its goal of reaching new markets and scaling its business.

“We’ve invested millions of dollars in 3D printing technology,” said Mr. Hartley. “i3DPS was created so other kinds of companies could get access to our capabilities. They use our website to send us orders for all kinds of projects, from single replacement parts and prototypes, to end-use production parts where they need 100 or even 1,000 pieces. We now have a whole range of industries coming to us, getting quotes and placing orders for 3D printed parts.”

To learn more about how iOrthotics leveraged front-end workflow software to grow their business by servicing new clients in new markets, read the entire case study HERE.