“Complexity is free” and “the cost is flat” are two of 3D printing’s biggest lies.

Neither is true, and I’m going to prove it. Right now.

MARKETING AND SALES

MARKETING AND SALES

Say you open a 3D printing service bureau. You want to fill it with work, so you hire sales and marketing people to build name recognition, drive traffic to your website, generate leads, and close deals. If you take an eCommerce approach you probably spend more on marketing. If you go old school, maybe you spend more on sales, but either way you make an investment.

QUOTING

A customer is thinking of doing business with you. If you have an online quoting system, maybe they use it. But if their job has any kind of complexity, you’ll most likely price it offline. Someone has to do the math. If you’re receiving hundreds of quote requests per month, you might even have a team of estimators banging out quotes.

Either way, whether you kill it with labor or kill it with technology, every quote has a cost. Less than half of those lead to revenue.

ORDER MANAGEMENT

Once an order comes in, you’ve got to manage it. If your customer is emailing you orders, all of his or her information has to be entered into your system.

Then as the job moves through your facility and is touched by different people, updates are made. If you’ve got a lot of work, you might even have a project or production manager overseeing those jobs to make sure everything is done correctly and on time.

MAKE READY

Often times, files that come in aren’t “print-ready.” They need to be fixed. Whether you charge separately, or build it into your price, file inspection and repair is an unavoidable reality.

Beyond that, there’s machine make-ready. Even though digital workflows reduce the amount, there is still some time involved in setting up any piece of equipment.

Once a product is 3D printed, it typically needs to be finished. Again, whether you charge separately for it or not, there’s still significant time and cost involved in getting those people, processes, and technology spooled up to complete the job.

LOGISTICS

Once a job is completed, it needs to be packed and prepared for shipment. There’s cost in materials (bags, boxes, labels, etc.) as well as the time it takes to enter and confirm shipping information.

TRANSACTION COST

Transaction cost can be defined simply as “the amount of money it takes to complete an order.” All of the costs above happen whether you’re printing one part or a million.

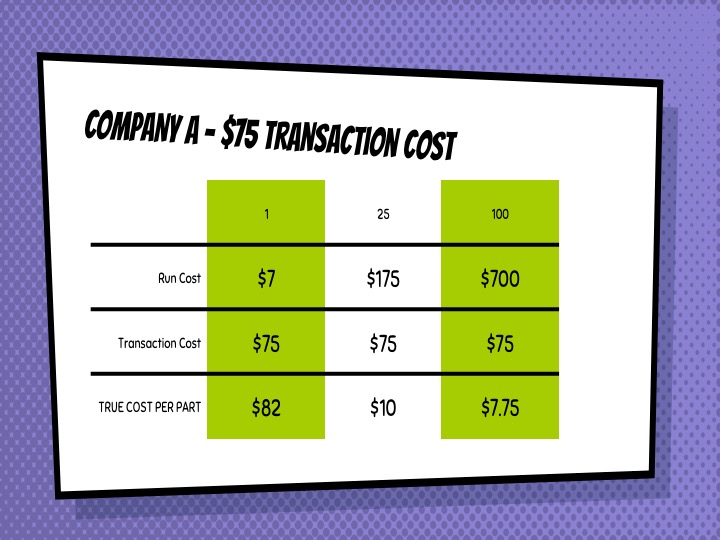

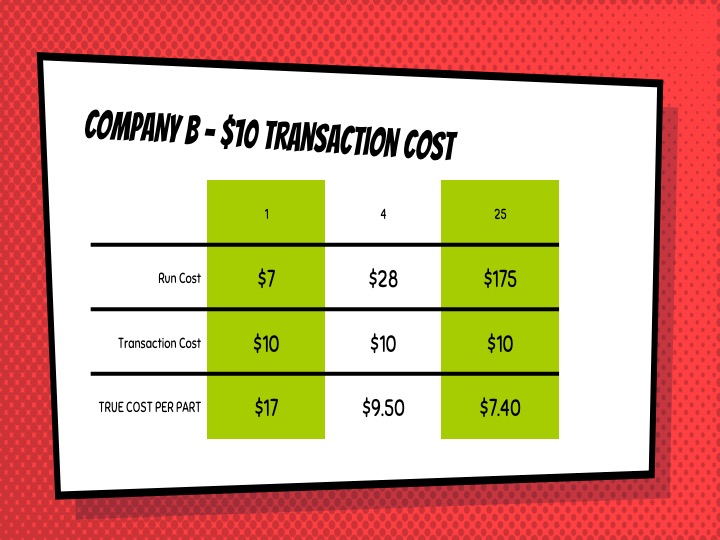

Let’s look at two scenarios. Company A has a transaction cost of $75 and they’re selling a part for $10 each. In the second scenario, Company B has a transaction cost of $10.

Company A needs a minimum of 25 units to outrun their transaction cost. Company B outruns it with orders of 3 units or more.

SHORT RUNS

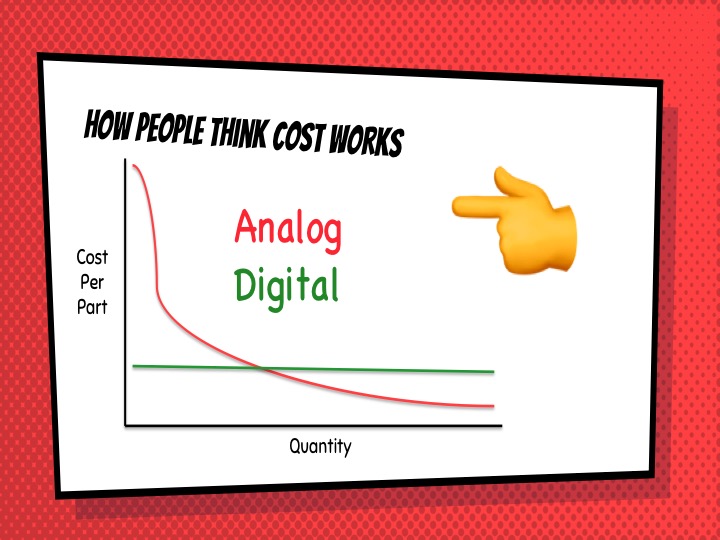

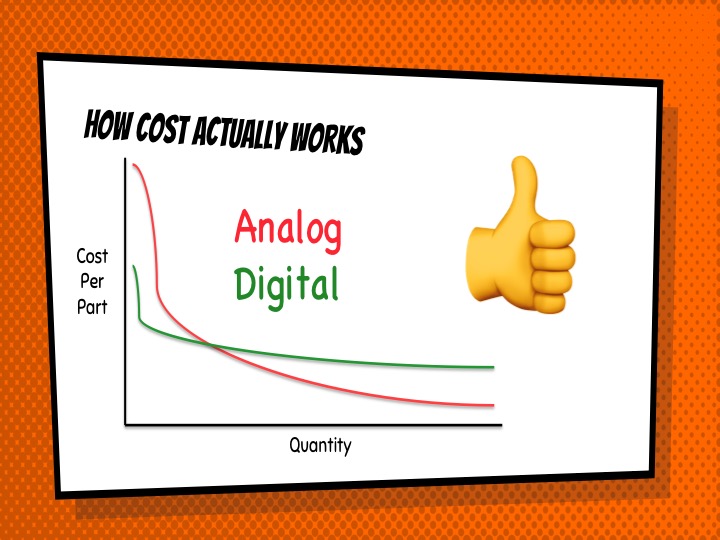

Lately I’ve seen a few presentations out there where people show graphs with a flat line demonstrating cost per part.

The examples above prove that’s not the case. But, rarely does anyone call bullshit.

Until you reach the breakeven, digital remains less expensive than analog. But it’s nowhere near flat. If your customer’s average order size is 100 units, you can pretty easily absorb transaction cost. If they’re only ordering one, or even 10, and you don’t account for it, transaction cost can easily sink your ship.

COMPLEXITY

When people in the industry talk about complexity, they’re often referring to customization and personalization. Whenever either are involved, customers must do significant work to communicate their preferences.

Whether it’s a customer service rep spending time on the phone with a client, or an investment in software and marketing to eliminate the labor and combat friction, more cost gets piled on.

Here’s the hidden problem. By encouraging customization and/or personalization all you’re really doing is driving order size downward. You’re catering to an audience of one. In a lot of cases, they only want one or a few of what you are selling.

As mentioned above, when order size decreases, transaction cost plays a bigger role.

SOLUTIONS

Let’s say you wanted to order a personalized bobblehead. Would you rather pay $20 or $85? Company A has to charge $85, or they will eventually go out of business. Company B can provide you with the same product, at a better price. They both use the same machines. Company B is just more efficient, and efficiency translates into savings.

It’s pretty straightforward really. If you’re going to push short runs and/or complexity, you have to fully understand your current transaction cost and make every effort to reduce it. You need to automate your workflow, and you also need high volume to spread fixed costs over as many transactions as possible.

So if you would, please do me a favor. The next time someone tells you that “complexity is free” or “the unit price is flat,” ask them about transaction cost…or just call bullshit.

This is an abridged version of an article that originally appeared on 3DPRINT.COM

For more on this topic, please check out the video.

For even more, check out my recent podcast with Chris Garrett at 3DPrinterChat.com